STATRAPID: the method of Rapid Pile Load Testing

Pile Load Testing

Allnamics is all about pile testing. With a wide range of testing techniques, Allnamics can test any pile for its integrity, bearing capacity, and stiffness. Being one of the pioneers in this field of pile testing, Allnamics founders have contributed significant knowledge to pile testing. Either Static, Dynamic, or Rapid Load Testing. The latter is one of the innovations of Allnamics founders for pile testing. In 1990 the Statnamic method was developed. Later followed by an alternative Rapid Load Testing: the StatRapid Load Test. That brings the total of testing techniques for bearing capacity to:

- StatRapid Load Testing

- Dynamic Load Testing

- Static Load Testing

- Bi-directional Load Testing

- StatNamic Load Testing

All these test methods can be performed onshore as well as offshore. For small micro piles as well for huge Monopiles.

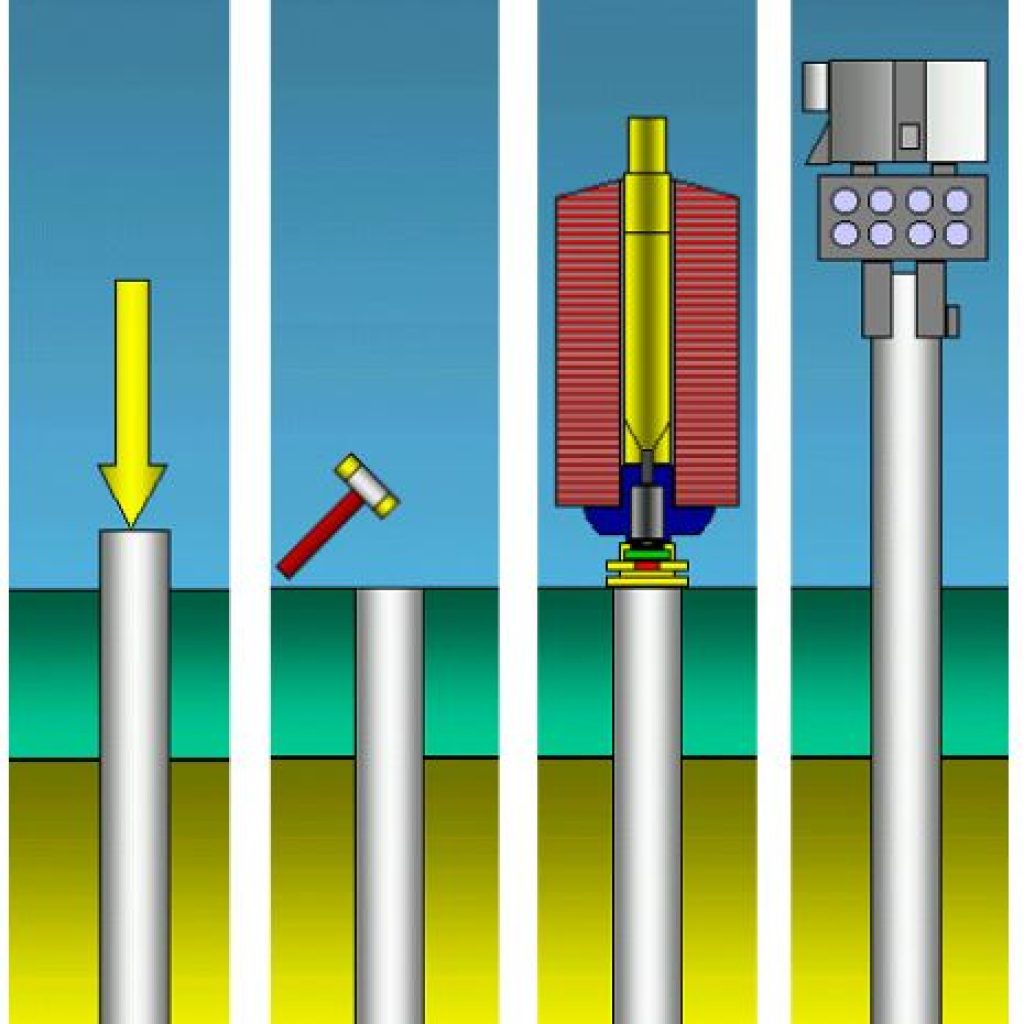

PDA Pile Driving Analysis

Foundation piles have been installed since… well, since always! Even the Romans knew their pile driving!

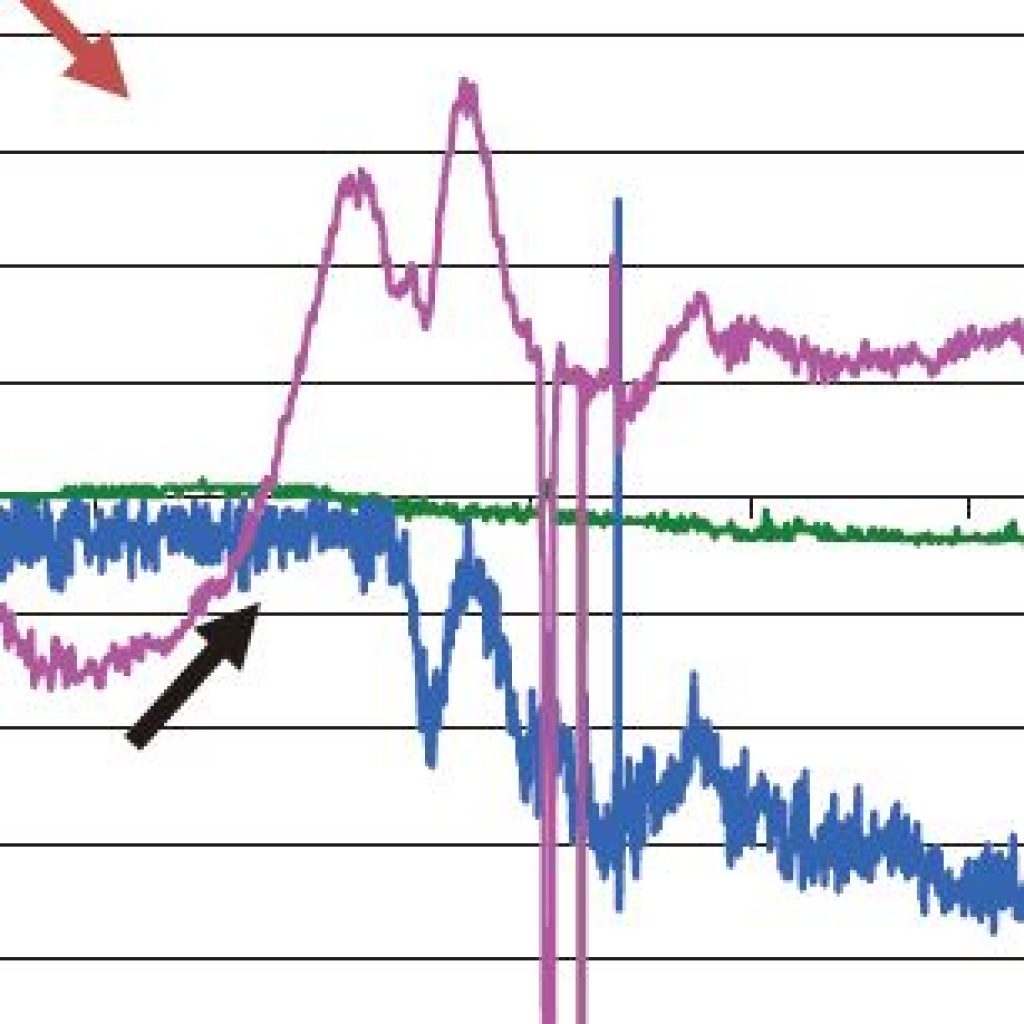

That implies Quality Assurance requires measuring during driving PDA (Pile Driving Analysis ) to check the installation process, e.g., pile stresses, blow counts, and hammer performance. Both for impact hammers and vibratory hammers (VDA Vibratory Driving Analysis).

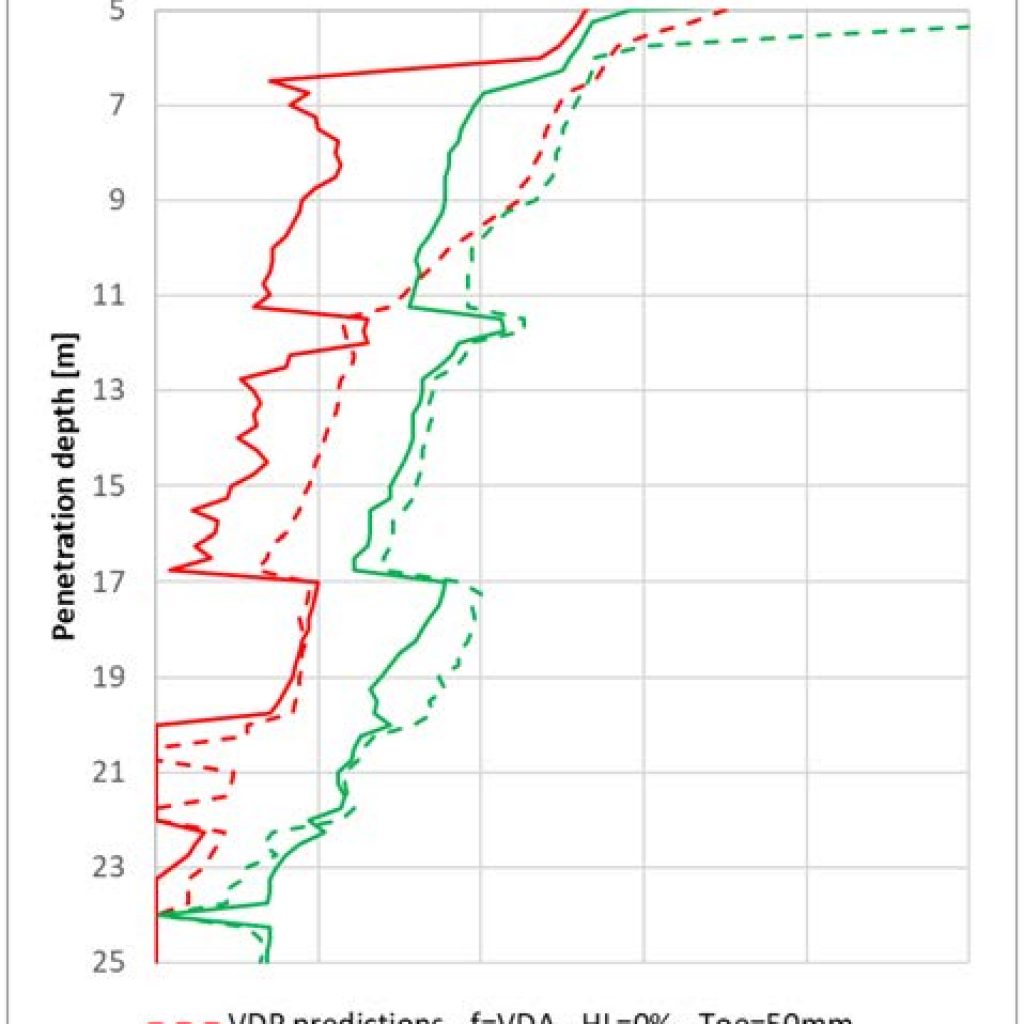

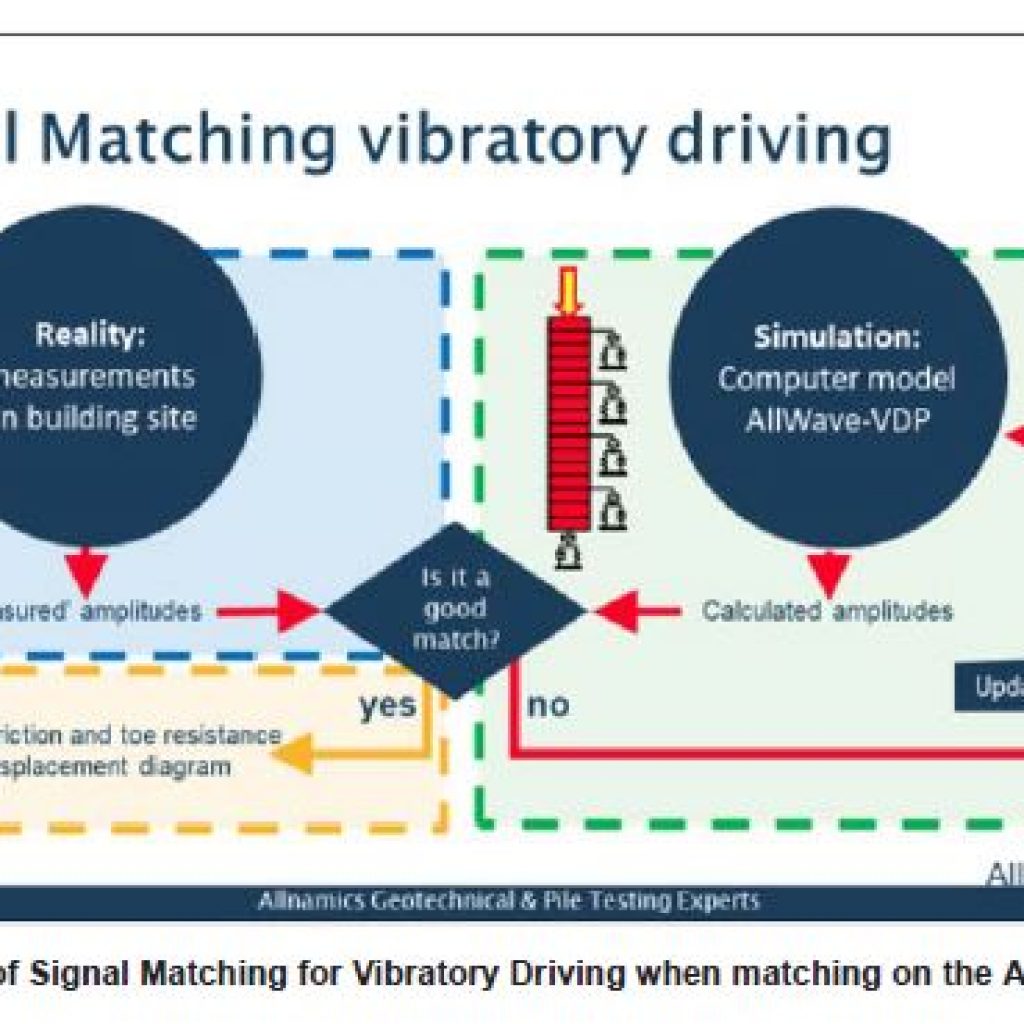

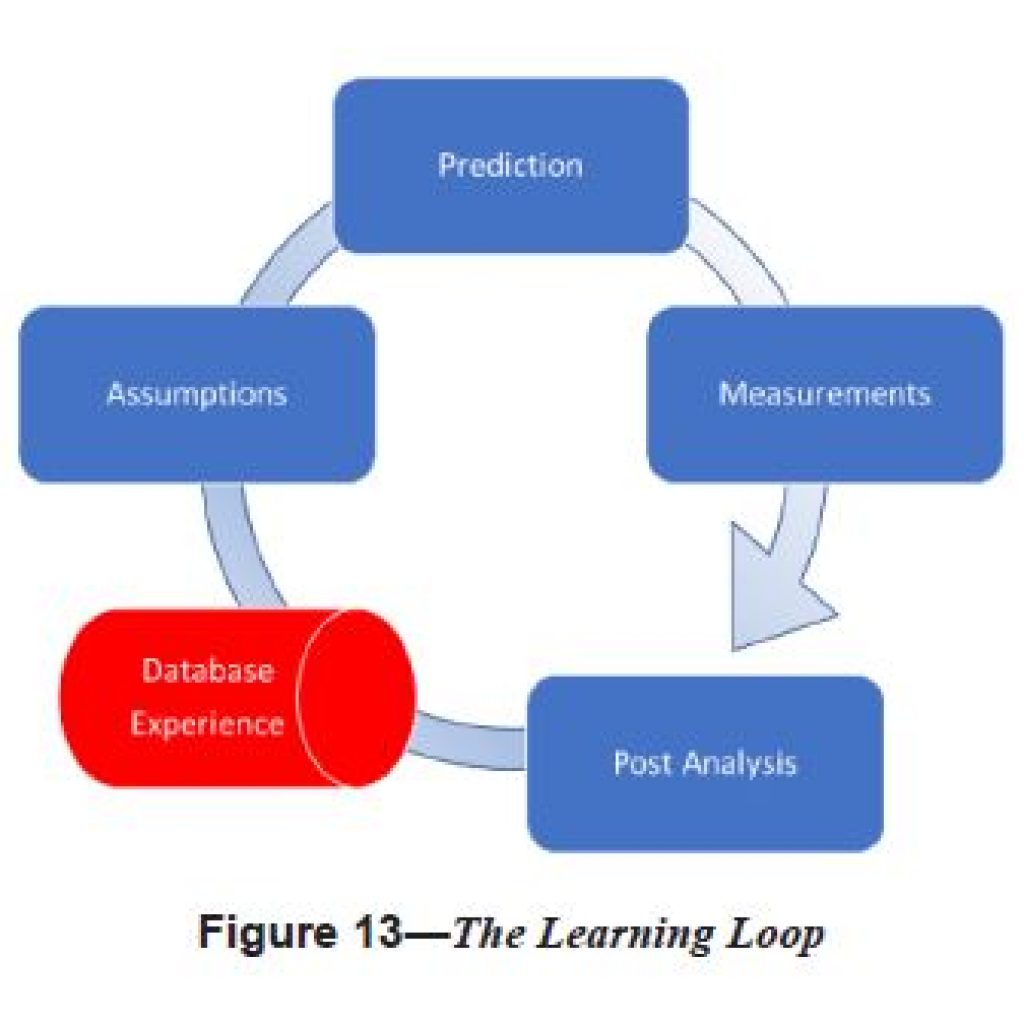

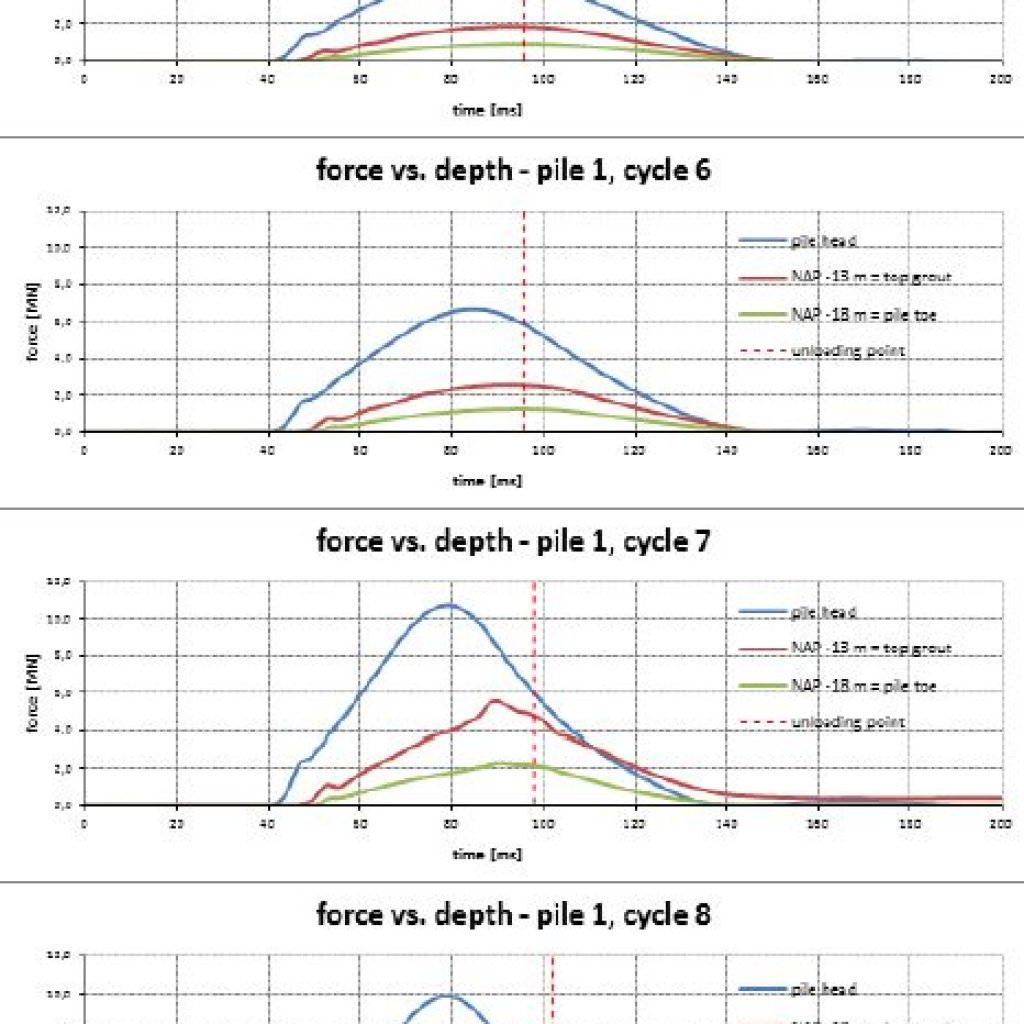

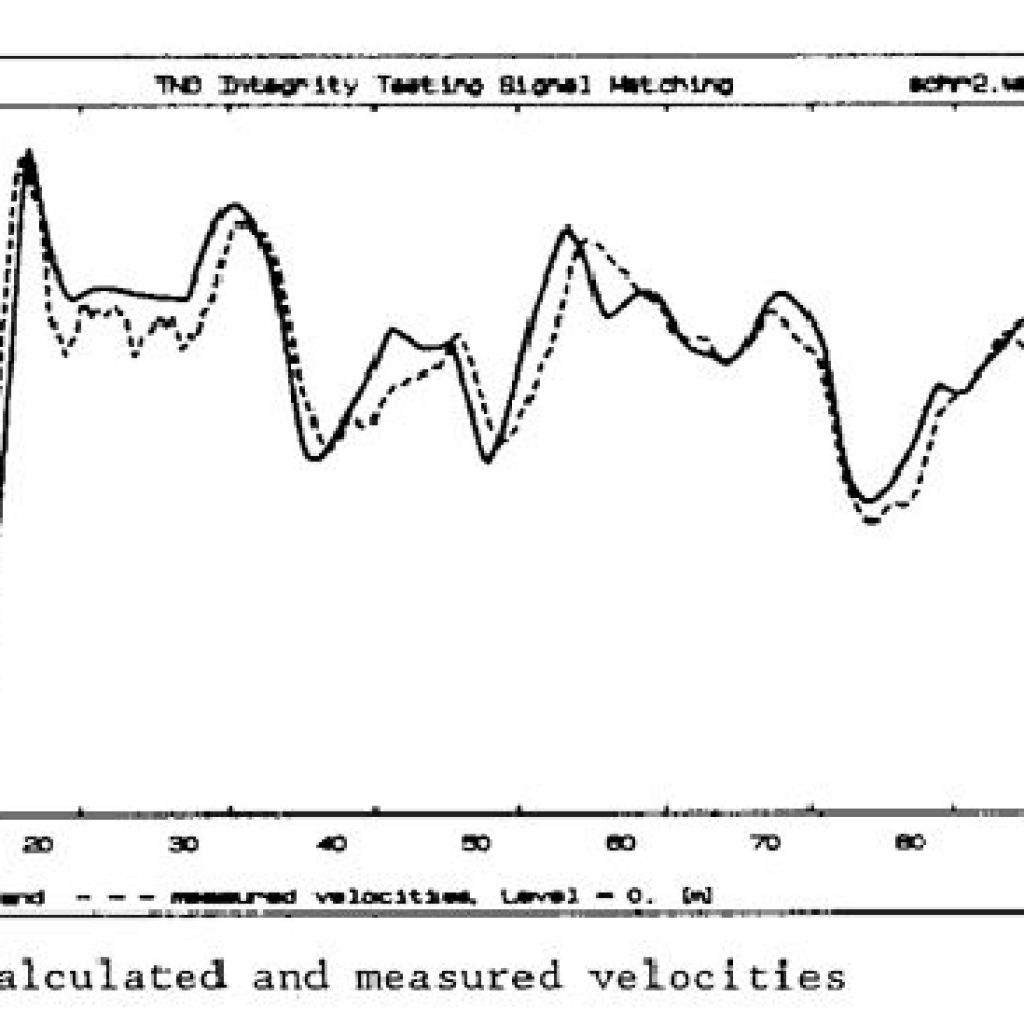

After driving, the bearing capacity will increase in time (aging, set-up). By measuring during a drive, the static pile/soil behavior and its static bearing capacity can be obtained by AllWave-DLT Signal Matching (DLT Dynamic Load Testing).

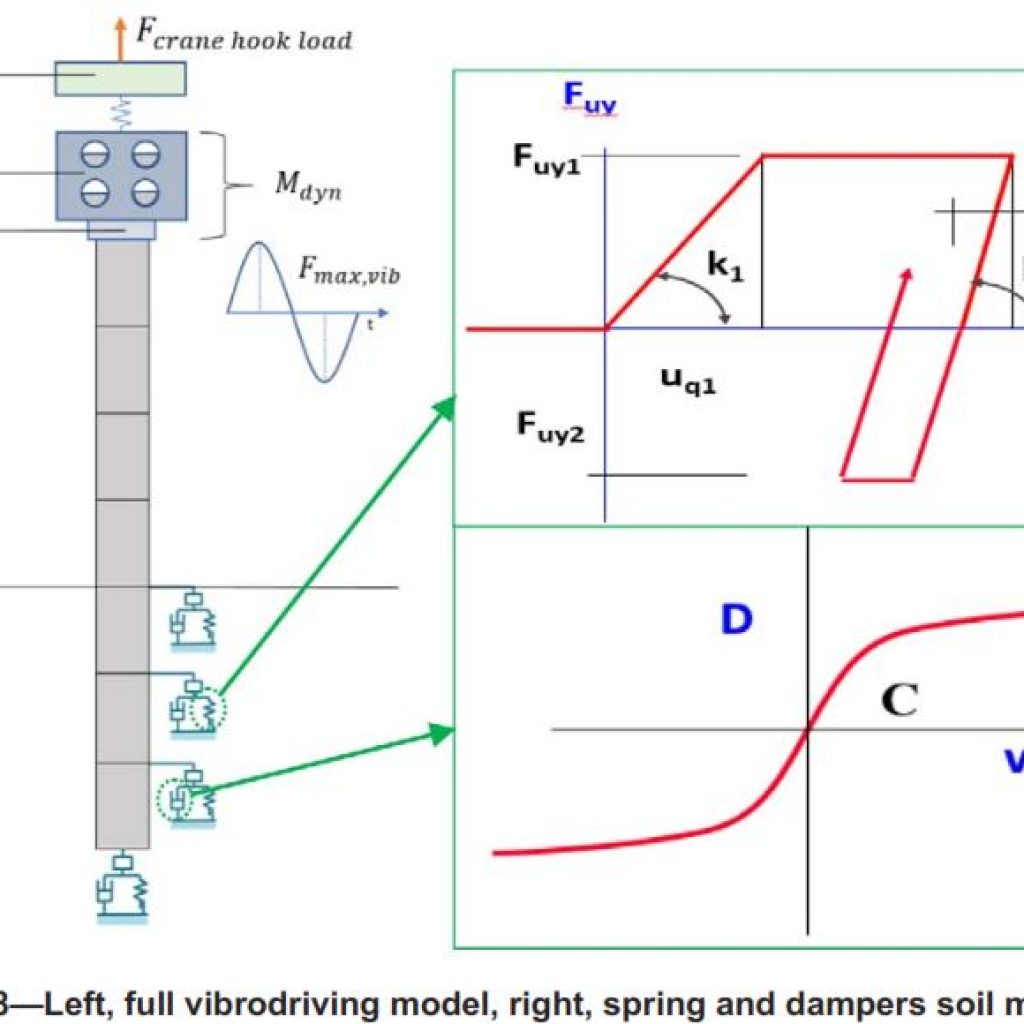

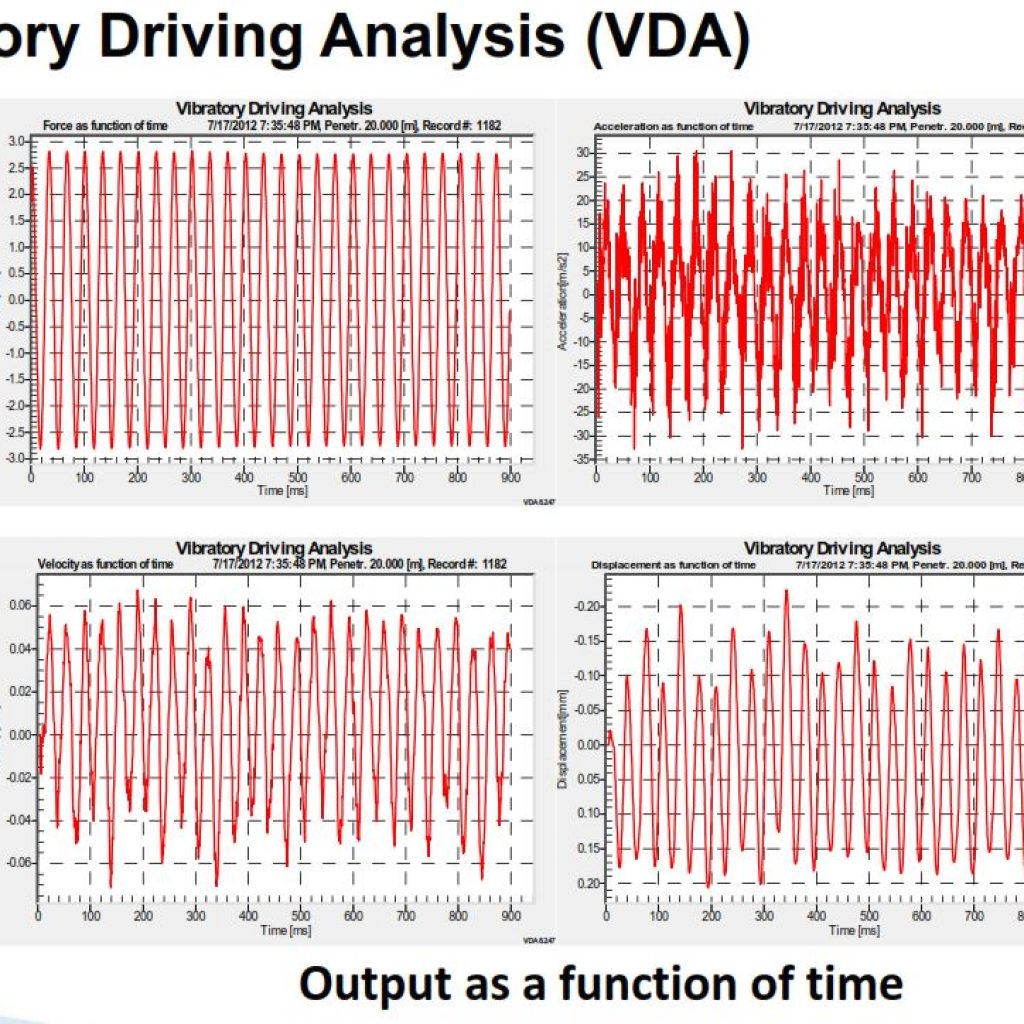

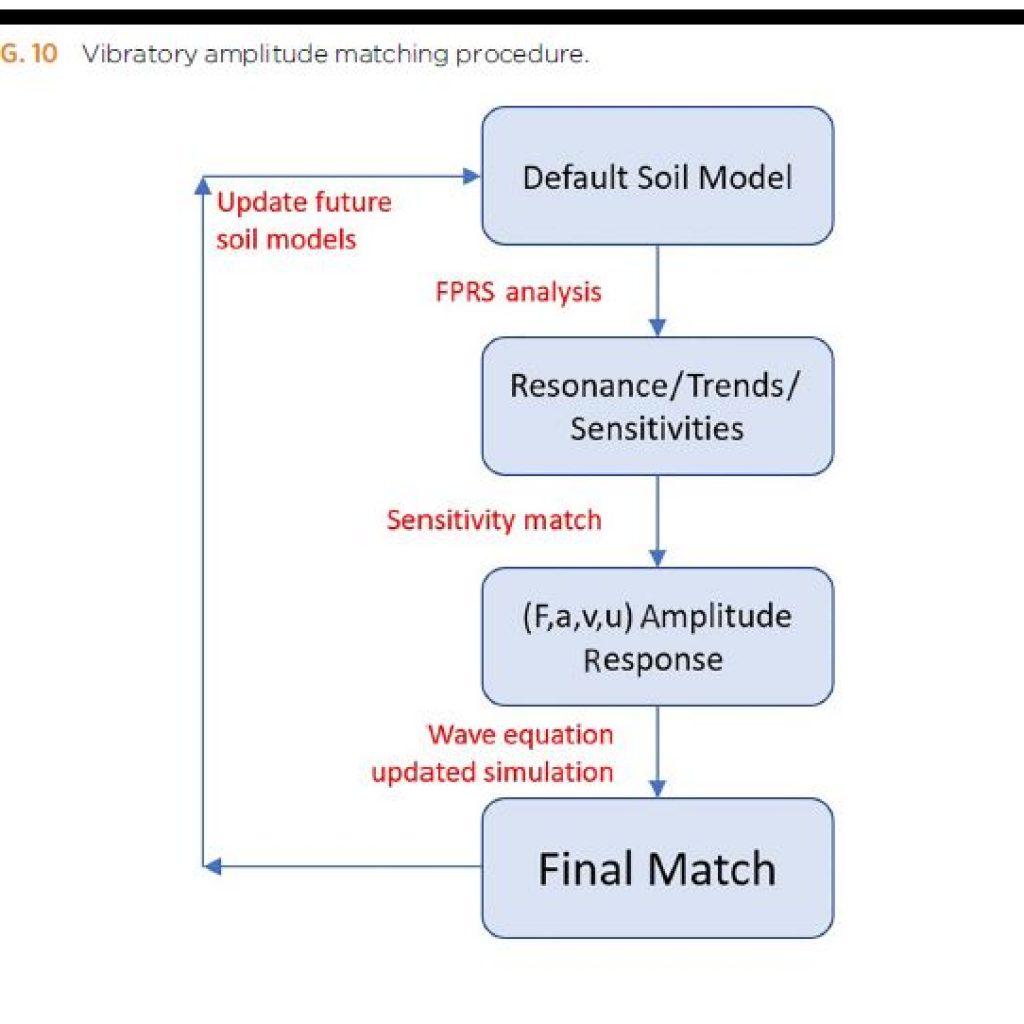

VDA Vibratory Driving Analysis

When piles are installed using a vibratory hammer instead of an impact hammer, comparable measurements, like with a PDA, can be performed.

During Vibratory Driving Analysis (VDA), all information during installation is monitored, including the performance and behavior of the pile, soil, and vibratory hammer. Monitoring pile stresses to determine fatigue of the pile material, penetration speed, hammer frequency, efficiency, and more, are part of total quality control for piles installed with vibratory hammers. For foundations piles and large diameter monopiles. Onshore and offshore.

SLT – Static Load Testing

Being the basis of all tests, Allnamics performs static tests, both in compression and tension. Vertical, horizontal, or under any slope. Axial or lateral.

Allnamics designed equipment dedicated to this type of test (see Allnamics Quad) to obtain high-quality readings of load and settlements.

The SLT is especially suitable for:

– Piles with relatively small capacity

– To determine design factors for shaft and toe resistance

– To determine load-displacement behavior

– Troubleshooting

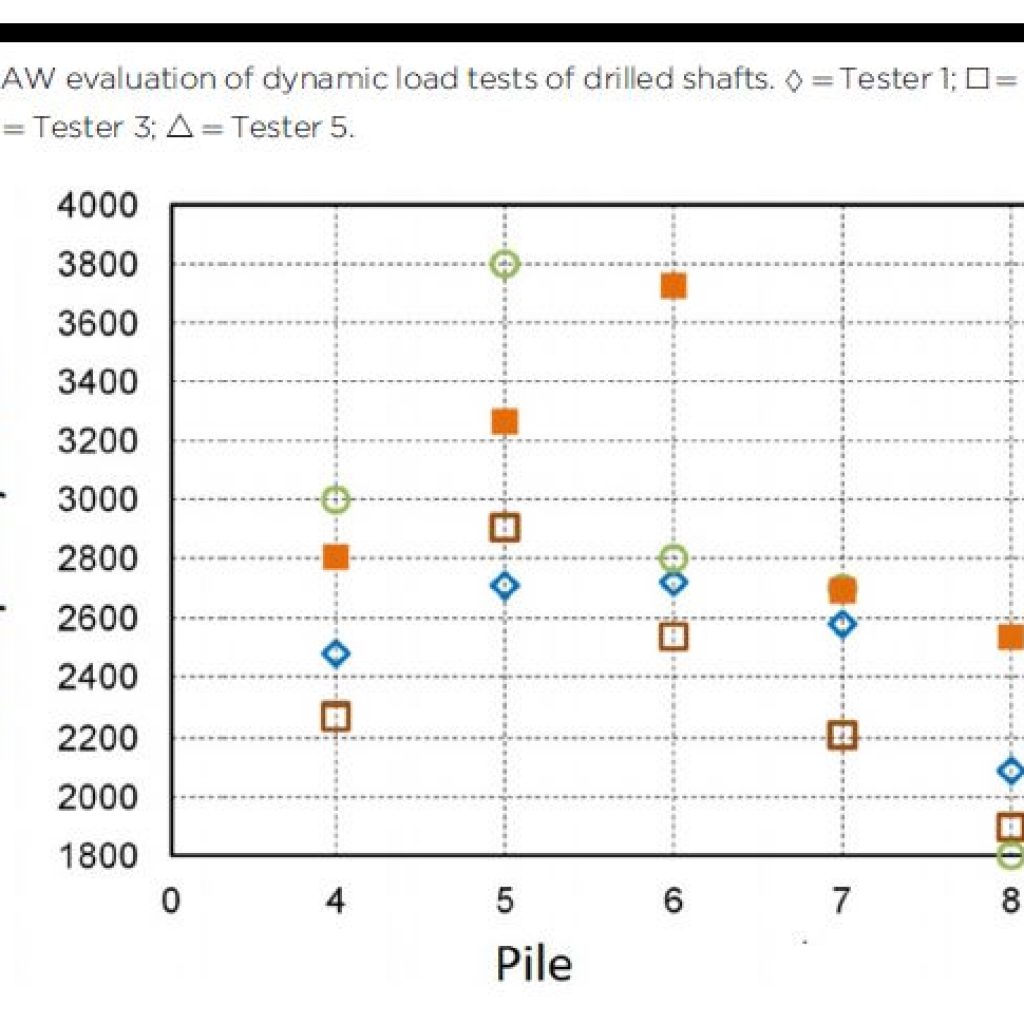

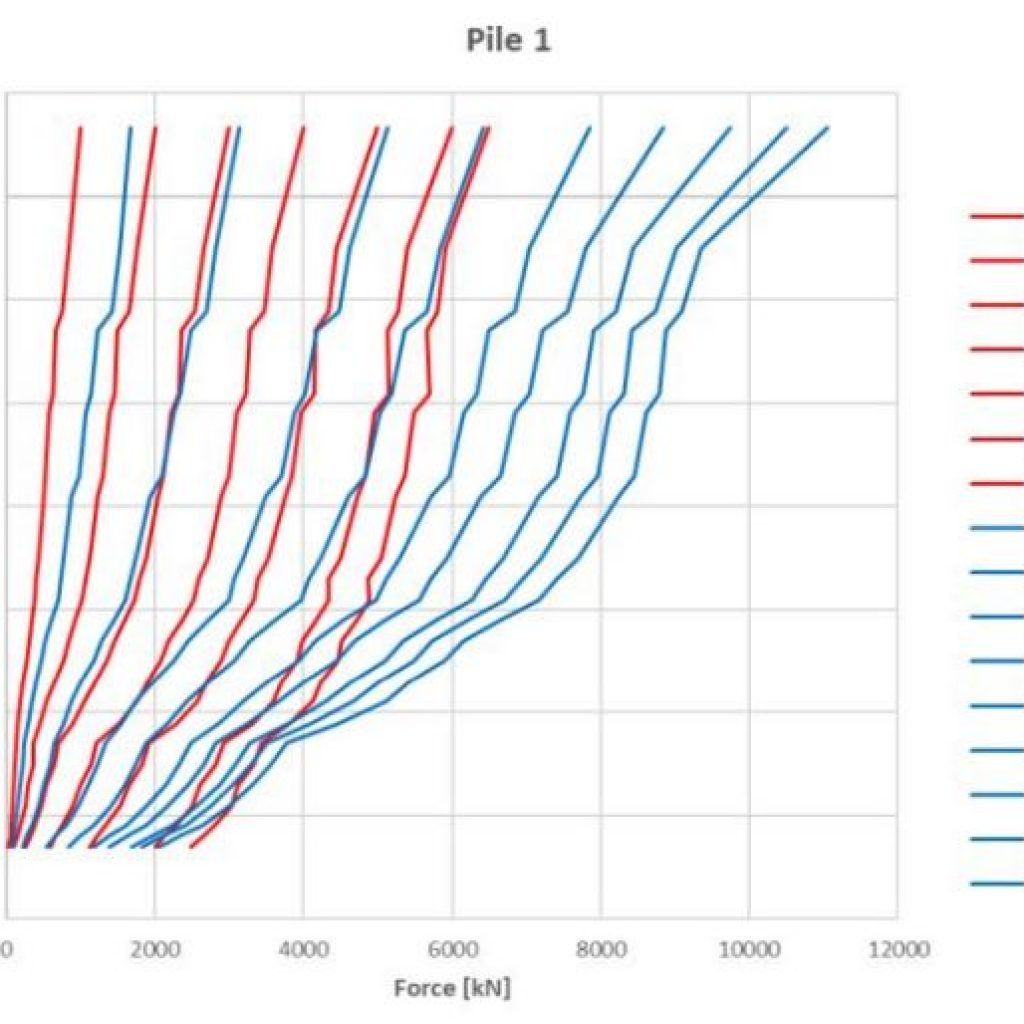

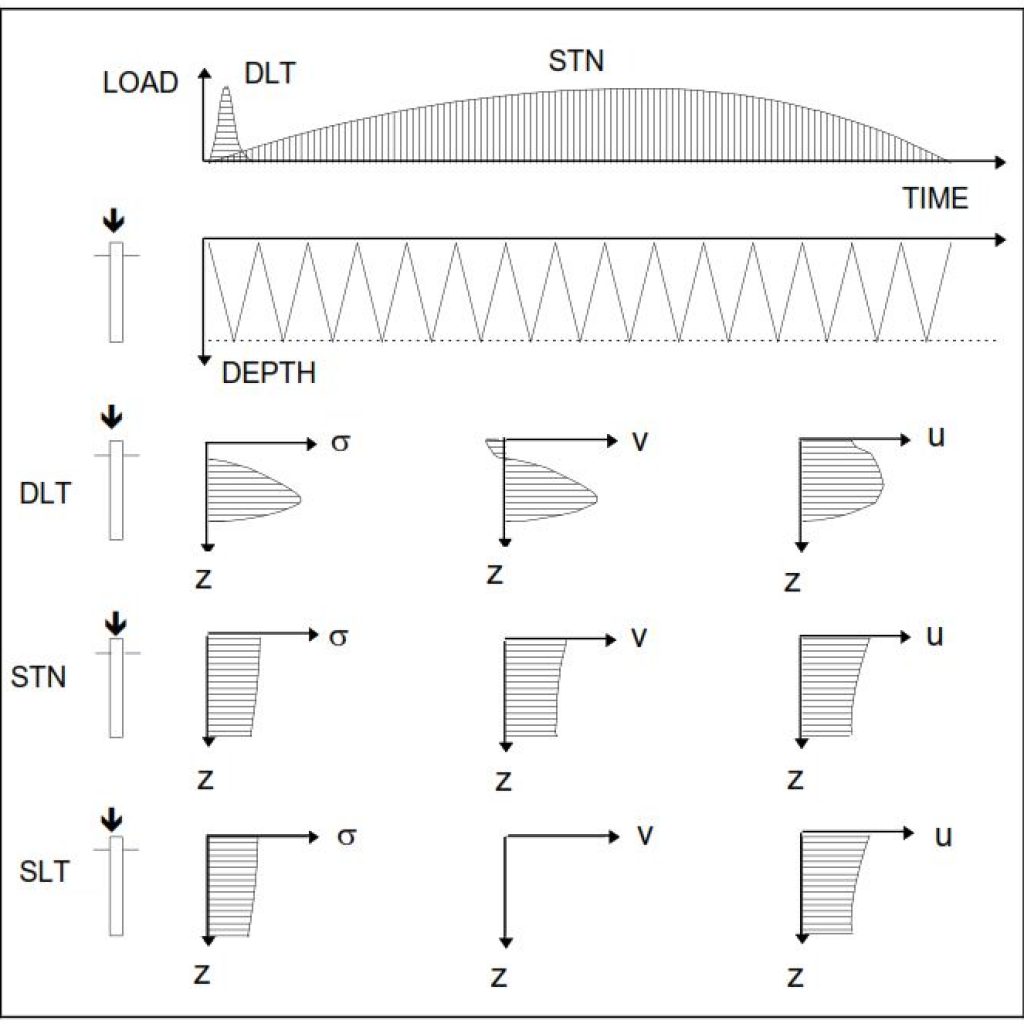

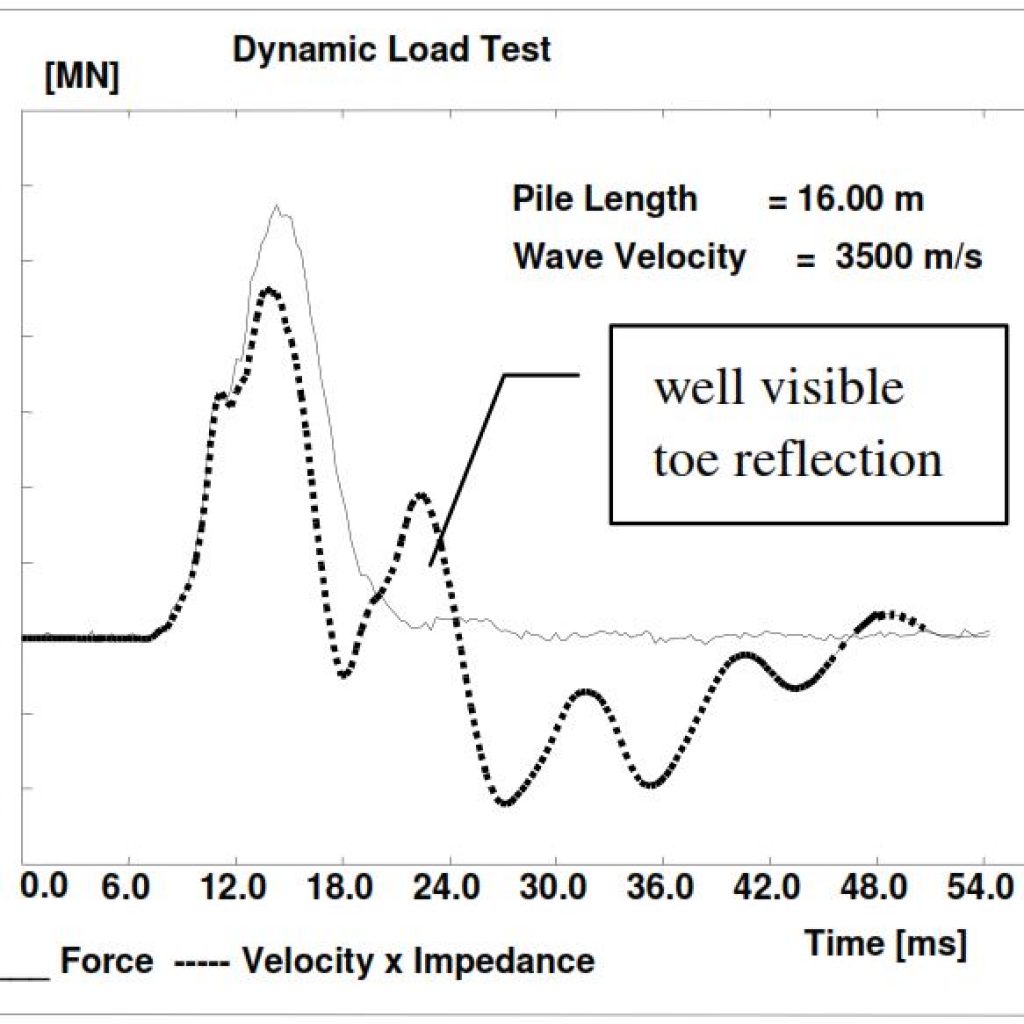

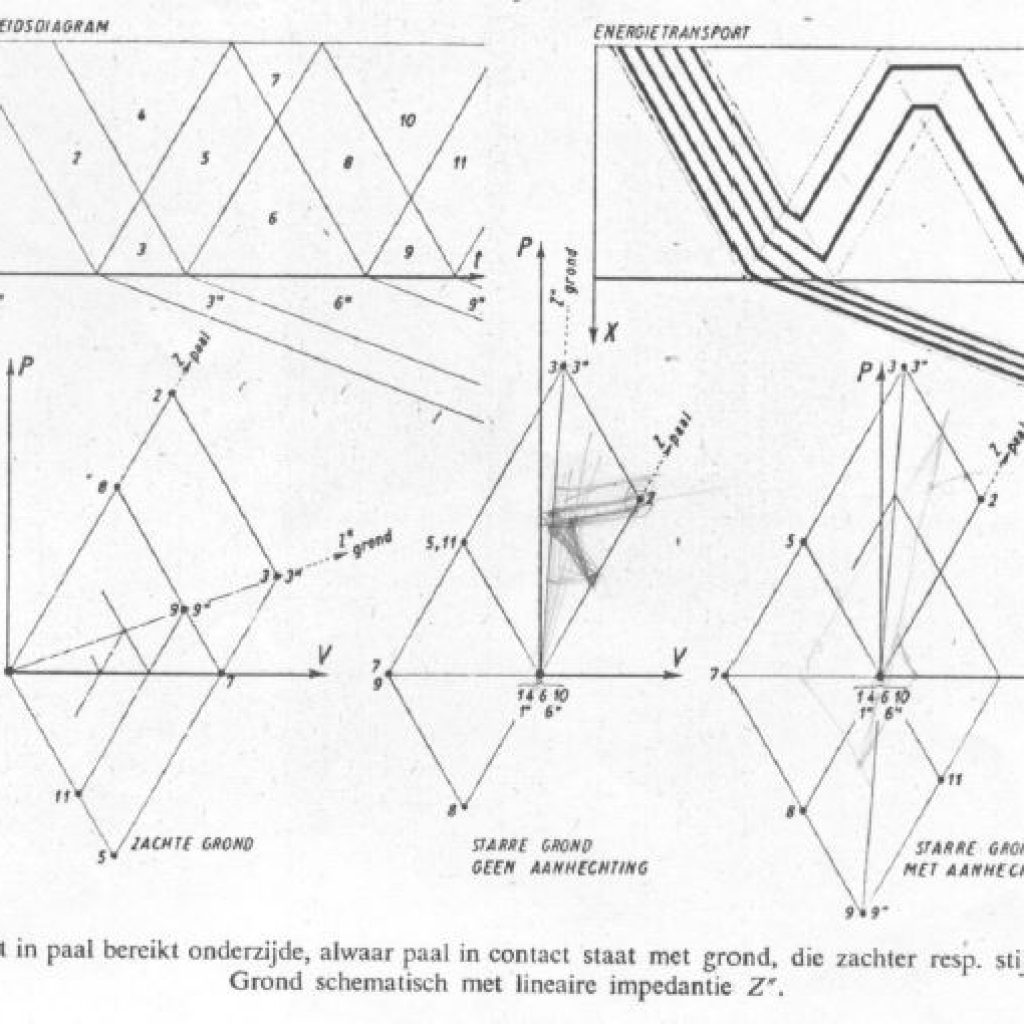

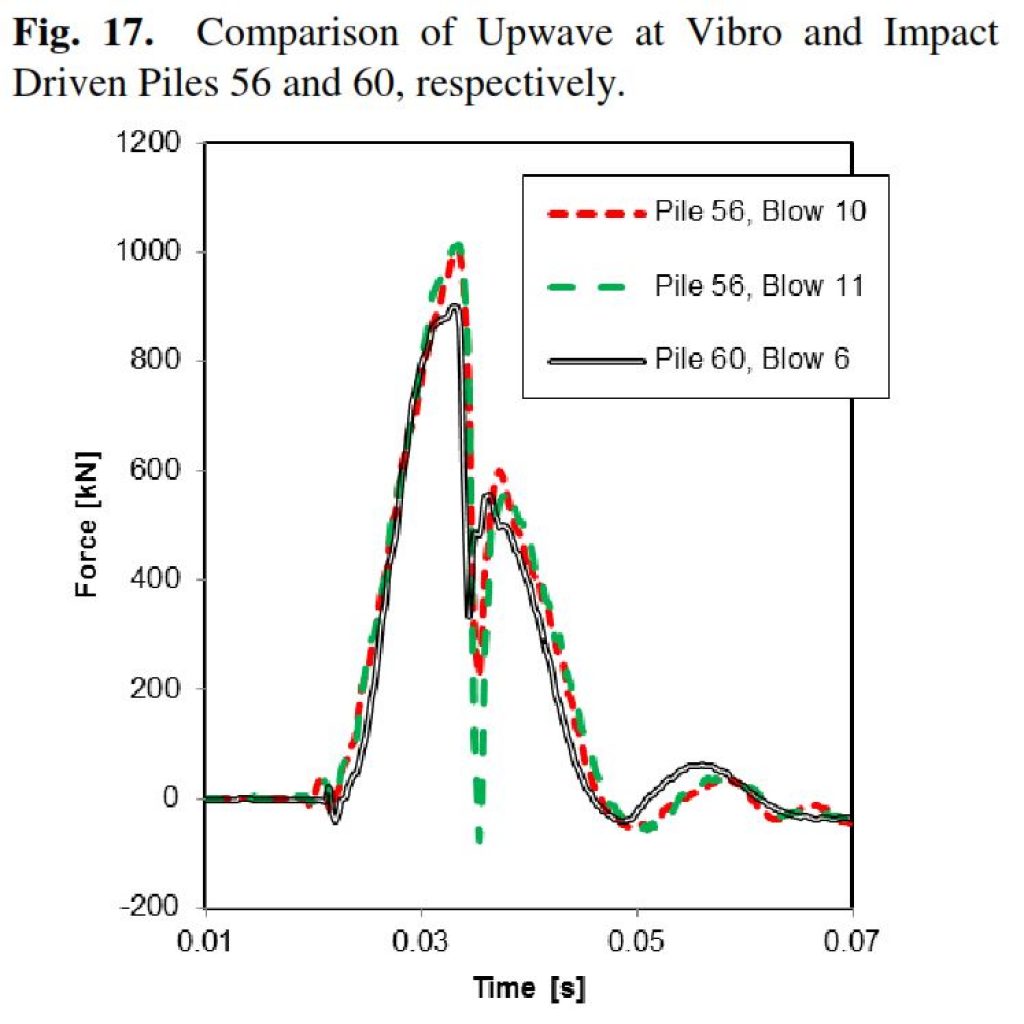

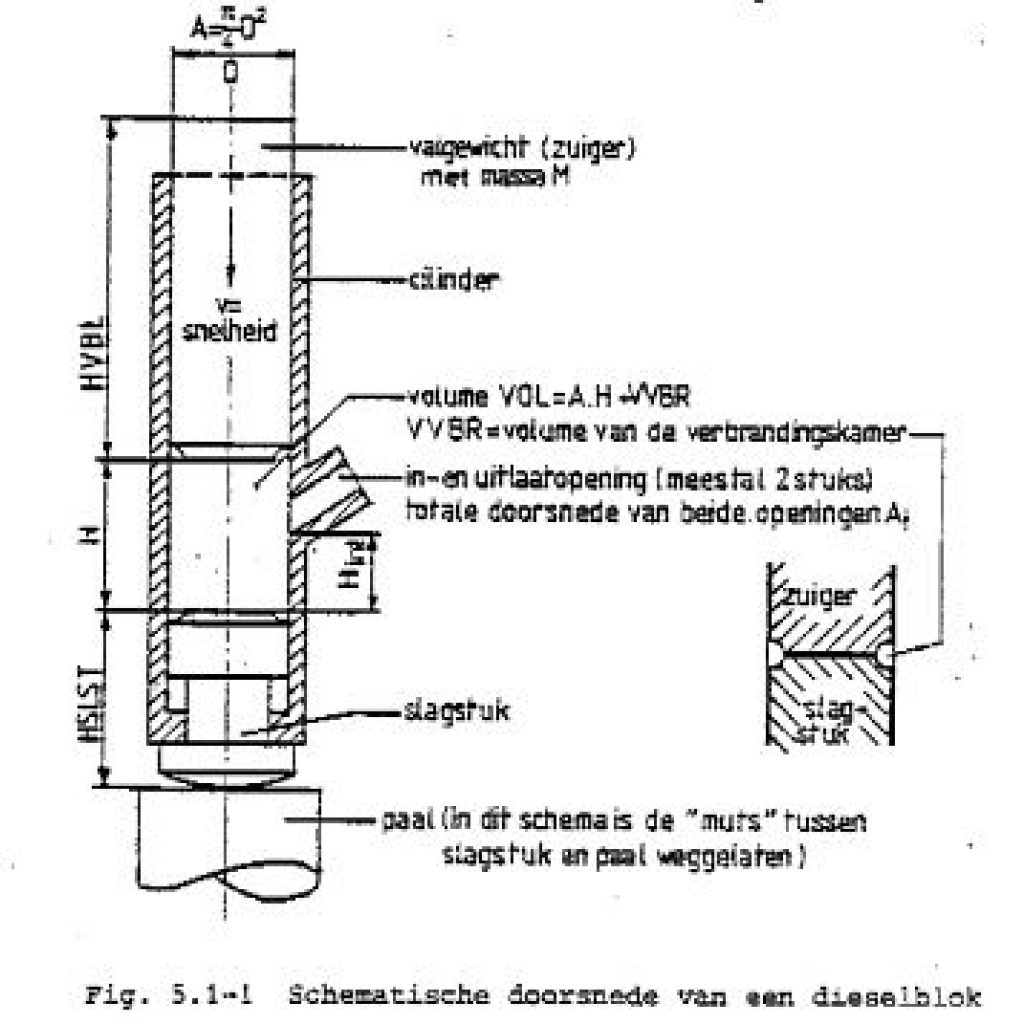

DLT – Dynamic Load Testing

The development of dynamic testing started somewhere in the fifties-sixties. In the seventies and eighties of the last century, the Dynamic Load Test became a mature testing method. At that time, offshore constructions were built for exploring oil at locations with, until then, unknown soil conditions. As an alternative to the Static Load Test, the Dynamic equivalent has positioned itself in the row of pile testing methods.

Allnamics’ founders are pioneers in this field. It led to a series of monitoring systems, starting with the FPDS (Foundation Pile Diagnostic System) up to the state-of-the-art Allnamics’ PDR.

The mean reason to perform Dynamic Load Testing is to obtain information about the pile behavior during (static) loading. The dynamic equivalent is much faster and less time-consuming than Static Load Testing.

The application of DLT (internationally also known as PDA or High Strain Dynamic Testing) is especially suitable for the following:

- Piles with high bearing capacities, where it’s hard to mobilize enough static force to load the pile statically up to failure, i.e., offshore piles

- Prefabricated concrete piles, able to resist the high impact stresses of the DLT

- Piles with a homogeneous cross-section along the shaft

- Offshore and nearshore projects

For other piles, other methods are more suitable. For instance, applying DLT to cast in situ concrete piles, bored piles, and CFA’s, the high impact loads lead to (too) high impact stresses with possible damage to the pile. Reduction of the impact load to limit the stresses to the concrete strength leads to a low mobilized bearing capacity. Furthermore, uncertainty in cross-section and concrete quality results in reduced accuracy of the analysis. These piles are preferably tested by Rapid Load Testing, StatNamic or StatRapid, for which the maximum stresses during the test are significantly lower.

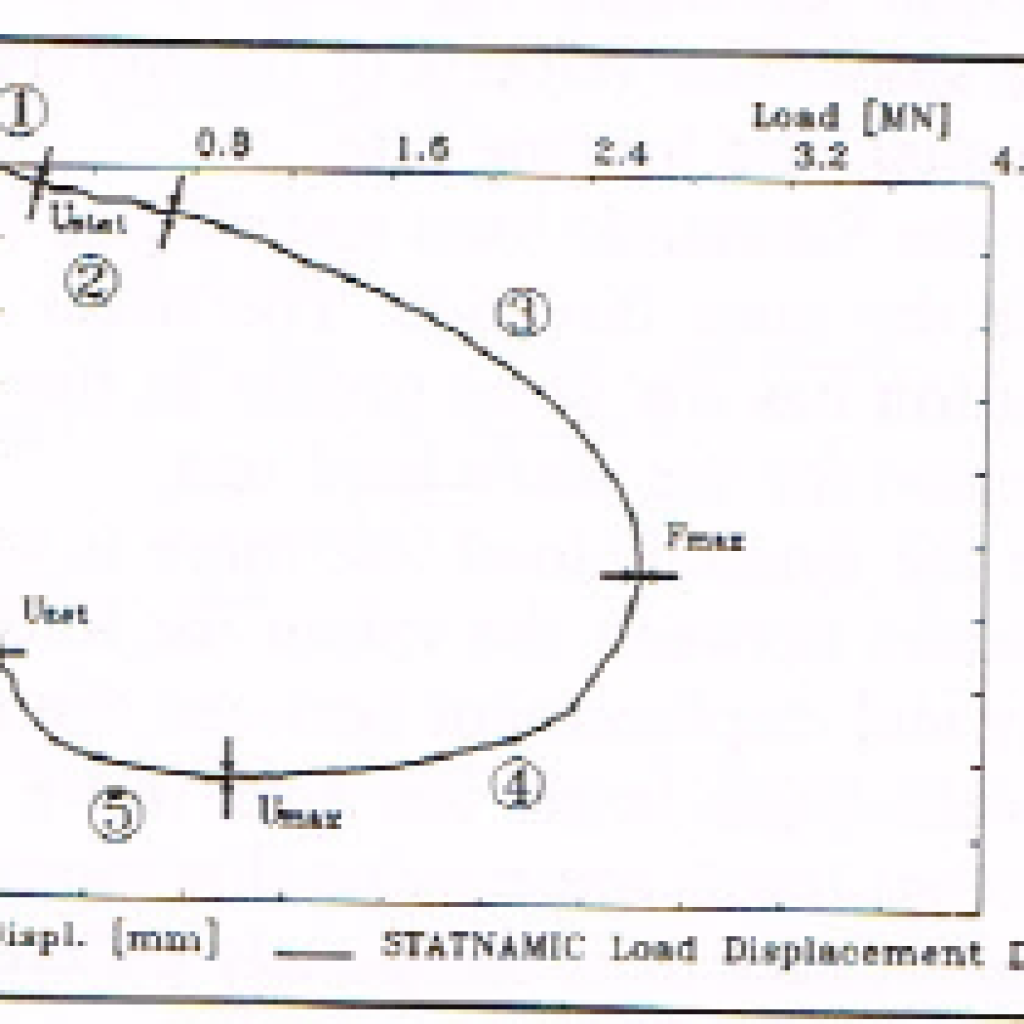

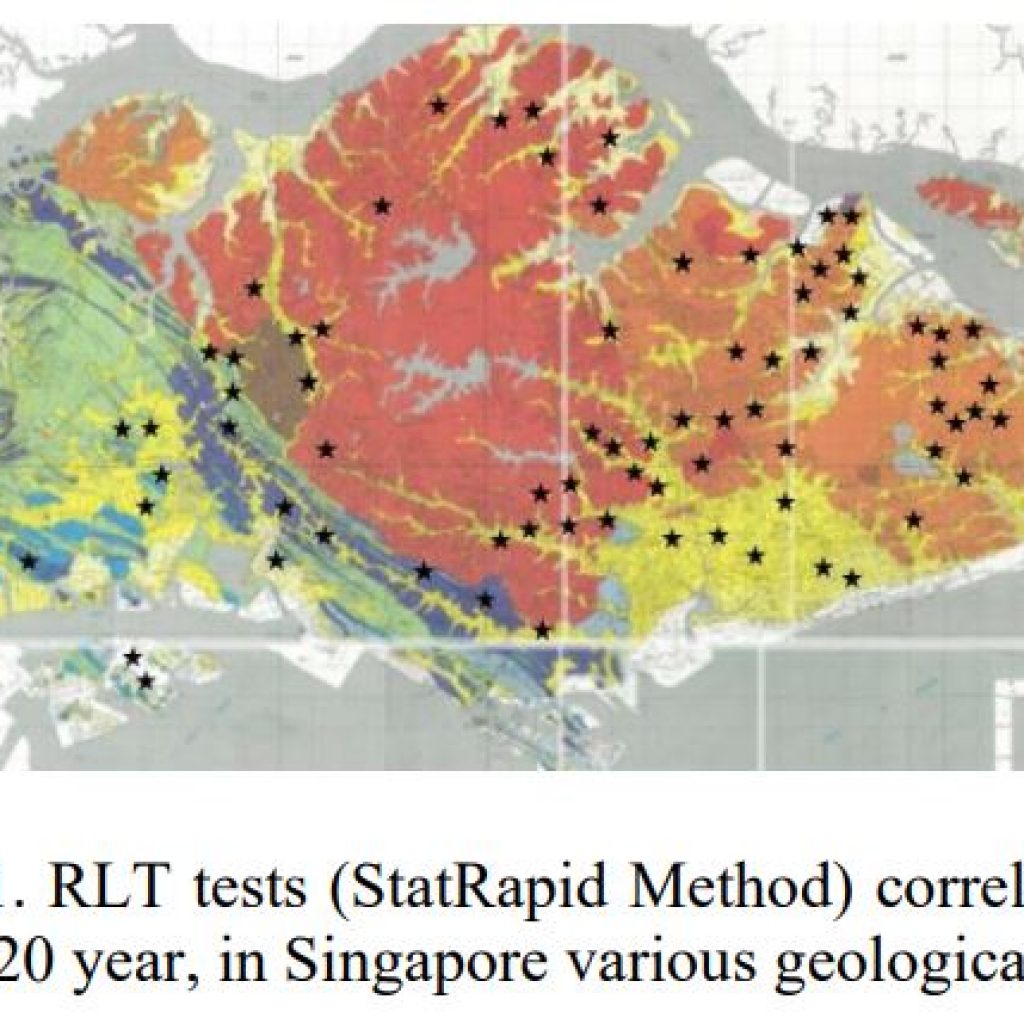

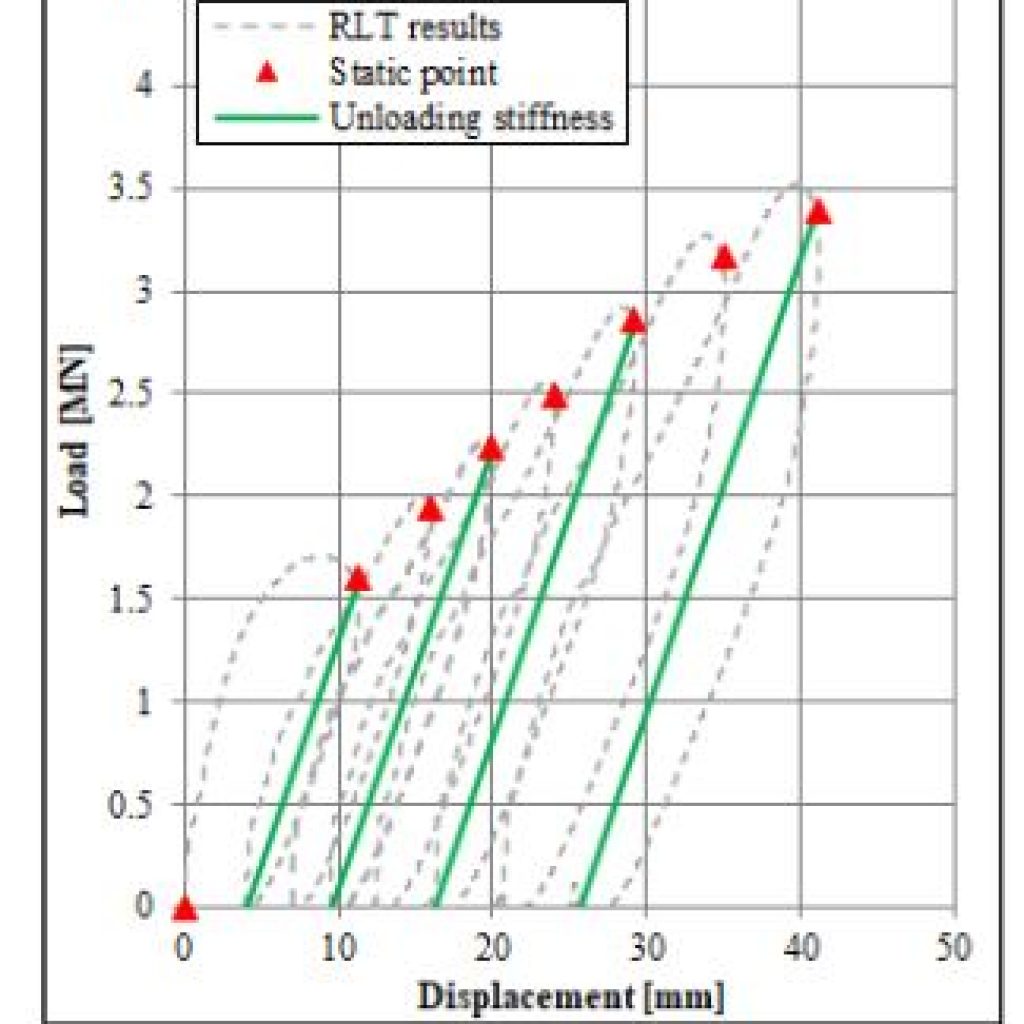

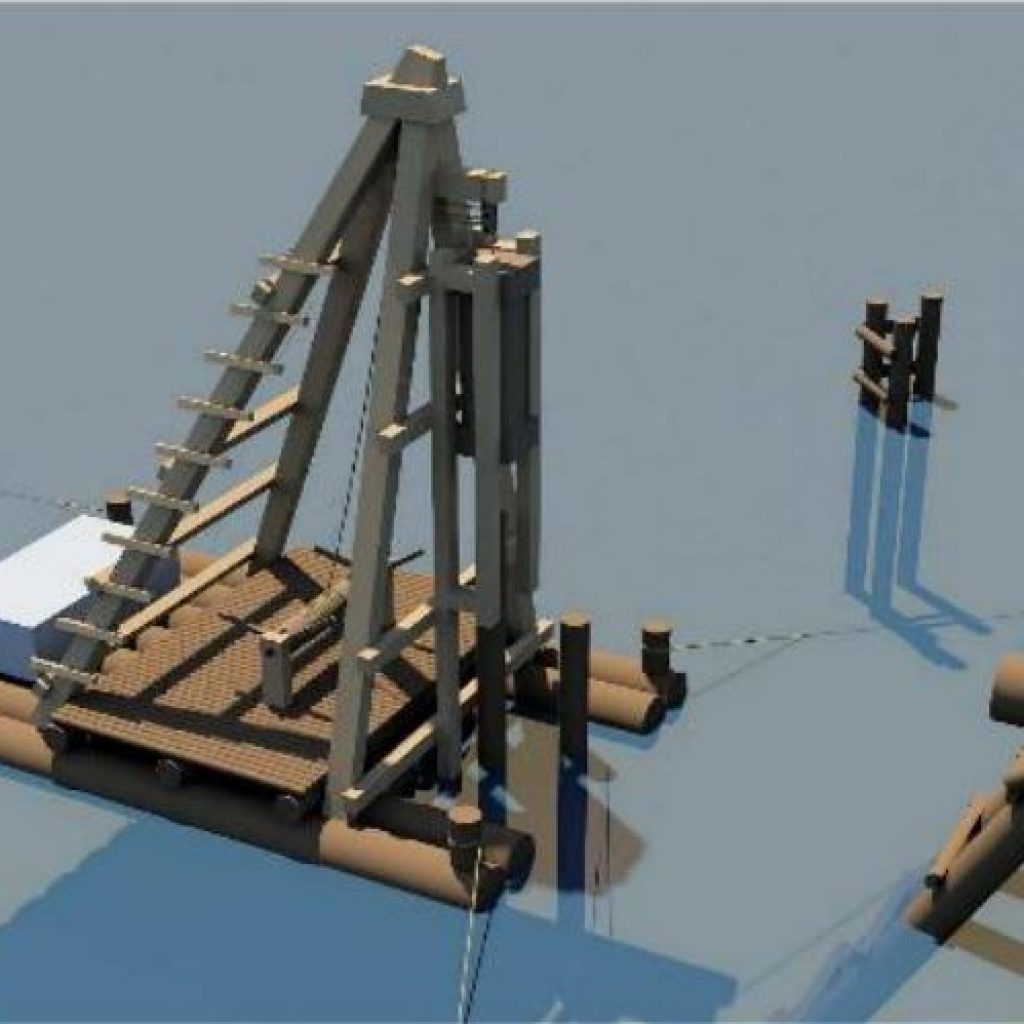

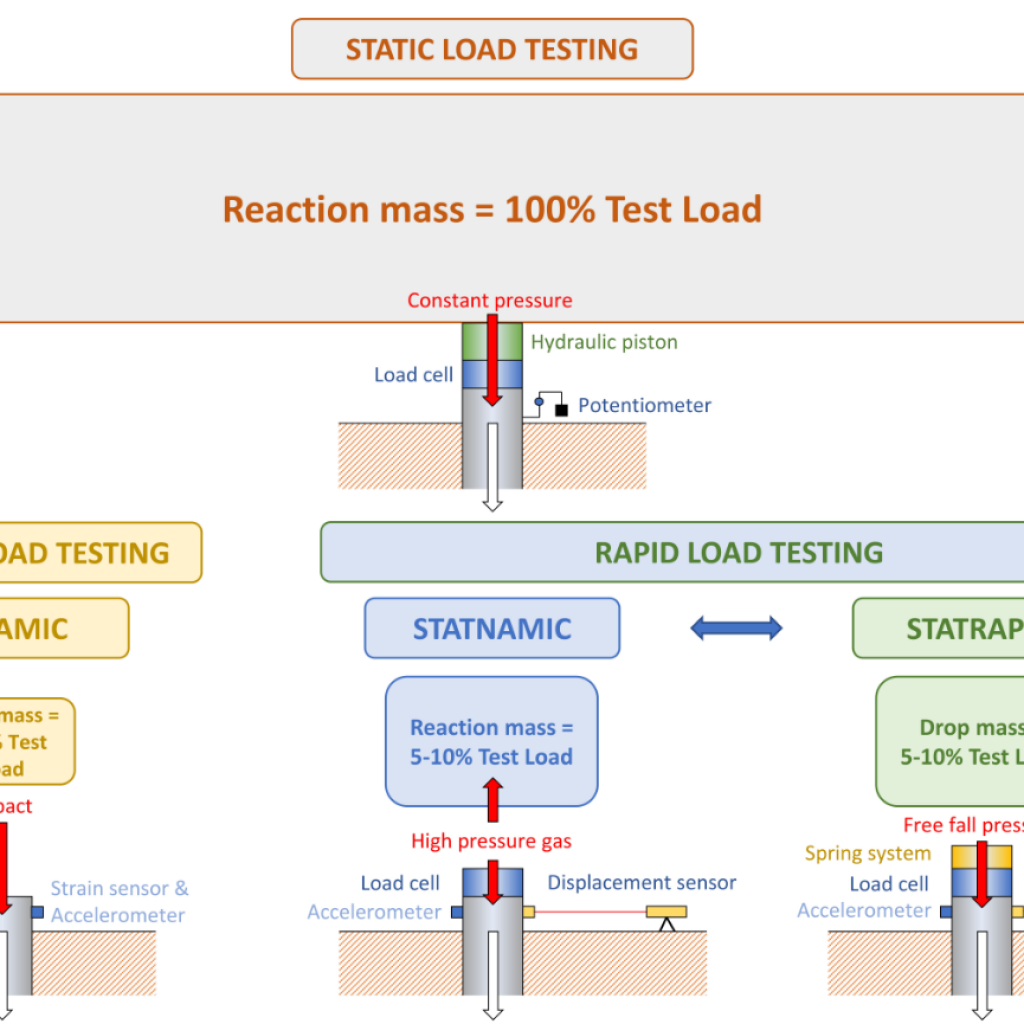

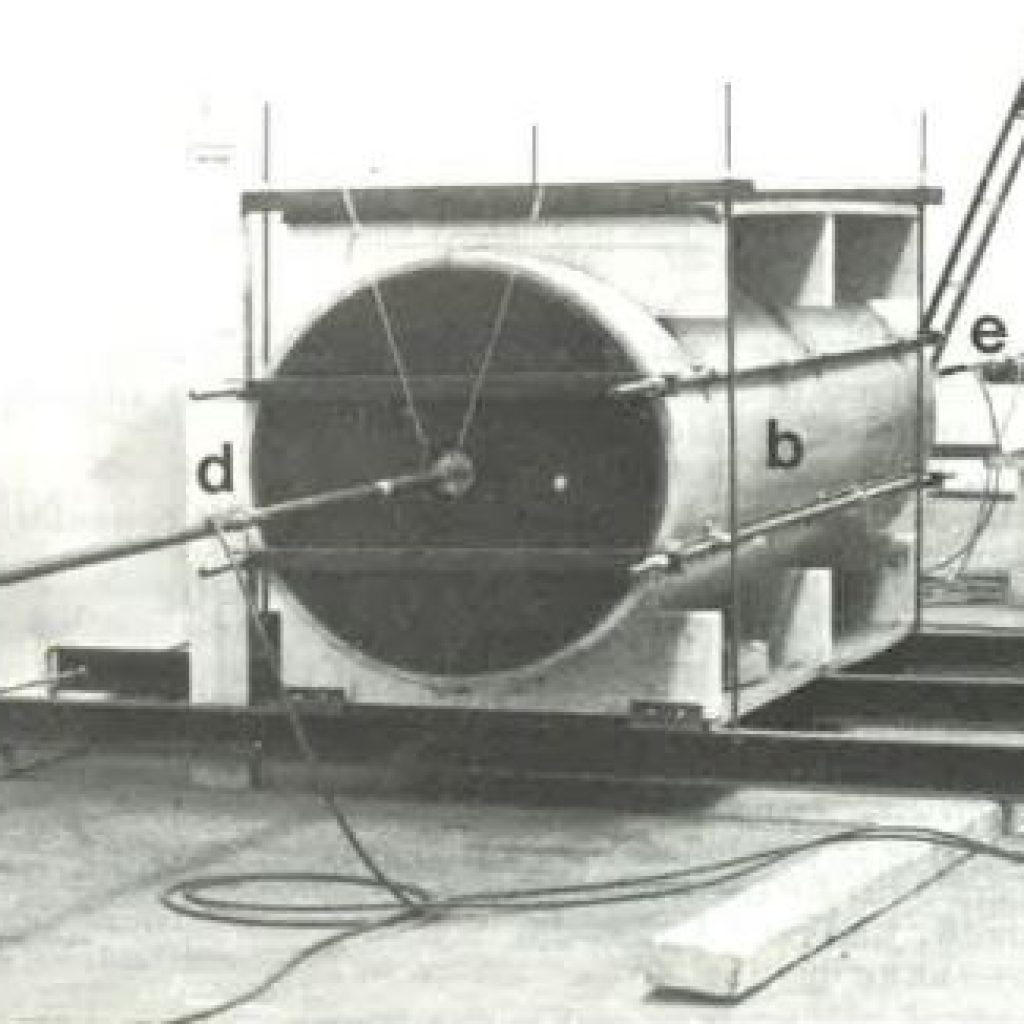

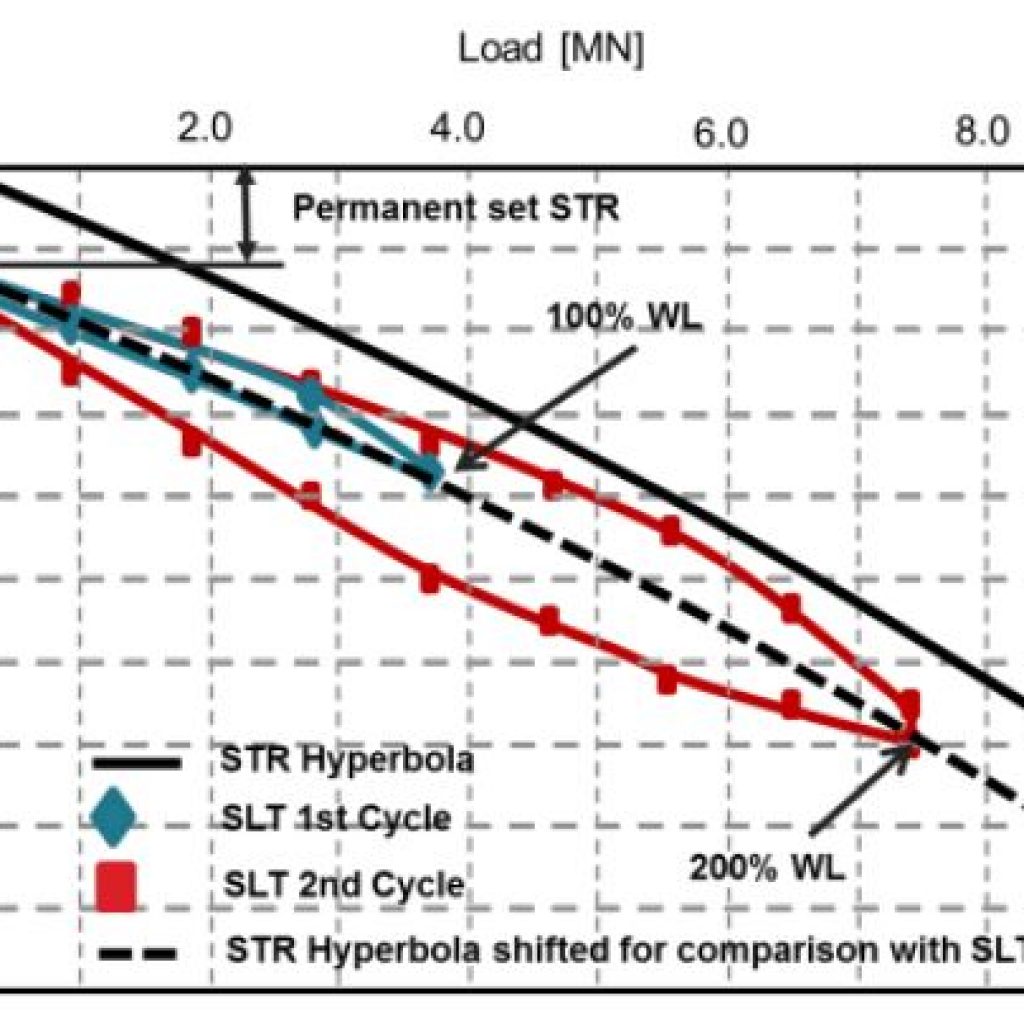

RLT – StatRapid Load Testing

Rapid Load Testing combines the benefits of static and dynamic testing. Quick and cost-effective like the Dynamic Load Test, accurate and reliable as the Static Load Test. Rapid Load Testing overcomes the disadvantages of those testing methods: no reaction frame, anchors, or dead weight as is required for the Static Load Test. And no user dependency on the results as in Dynamic Load Testing.

Allnamics can choose to perform Rapid Load Tests with two different types of testing. For test loads up to app 20 MN, StatRapid will be often used. For higher loads, the Statnamic Load Testing method is available. With this test method, loads up to 65 MN, and even up top 150 MN, are possible.

Do you want to know more about Rapid Load Testing? Contact Peter Middendorp at pmiddendorp@allnamics.com

Bi-directional test

The Bi-directional test is an alternative to the Static Load Test for bored concrete piles. A characteristic of this type of pile testing is that the load is applied somewhere halfway in a pile instead of at the top of the pile.

A device, the cell, is cast into the concrete, somewhere halfway or near the pile toe to measure force and settlements at this level. The cell pushes the upper pile part upward, being the counter force for the downward test load on the lower part. After the test, the measured results are used to construct the load-settlement graph comparable to that of a Static Load Test.

The Bi-directional test will be applied for piles with higher capacities, with significant shaft friction, to mobilize enough counter force to mobilize the shaft and toe resistance of the lower part.

Pile Integrity Testing (Sonic Integrity Testing)

The Sonic Integrity Test was developed by the engineers of Allnamics in the sixties and seventies of the last century.

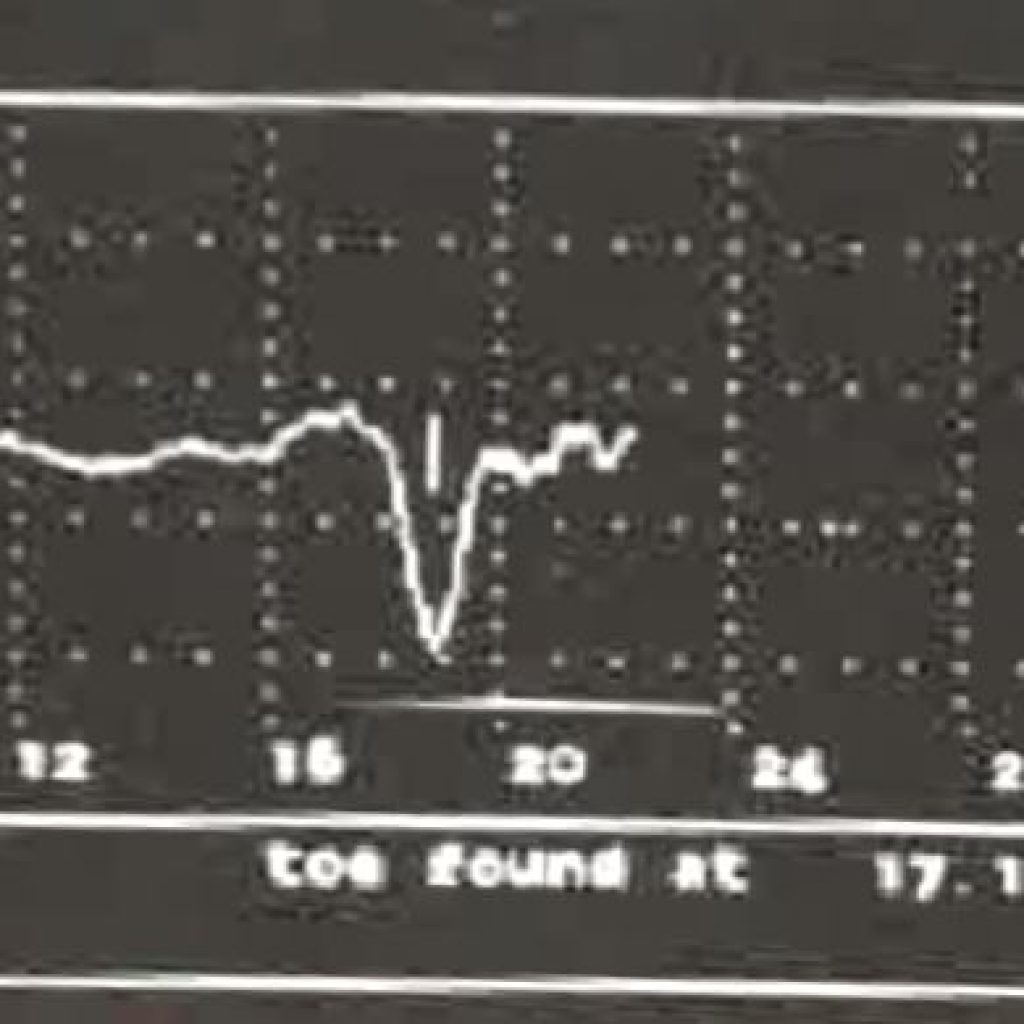

The test determines imperfections in concrete piles: Cracks, changes in cross-sectional area, soil inclusions, voids, and other imperfections.

The Pile Integrity Test or Sonic Integrity Test is the first, fast and rough, check on the quality of cast in situ piles. The method is fast and quick, so all piles can be tested easily.

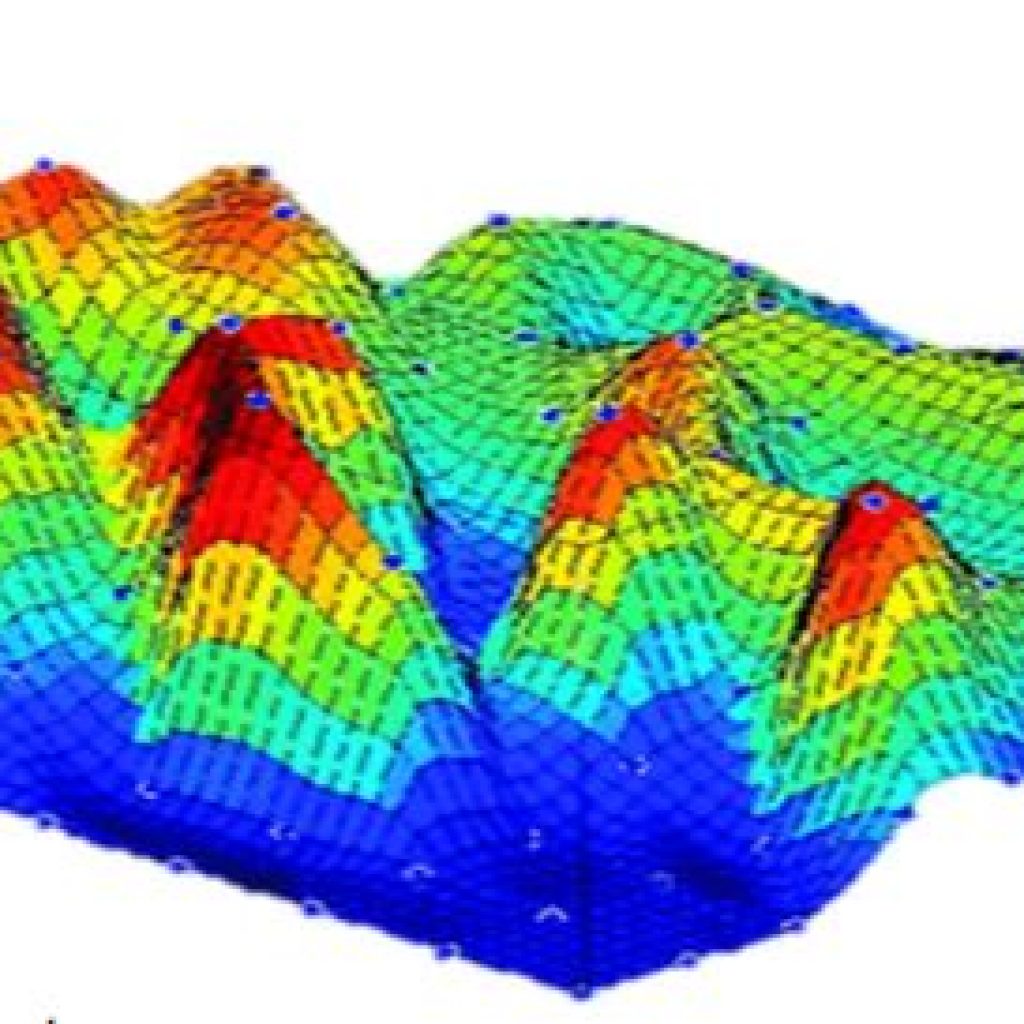

Sonic Logging

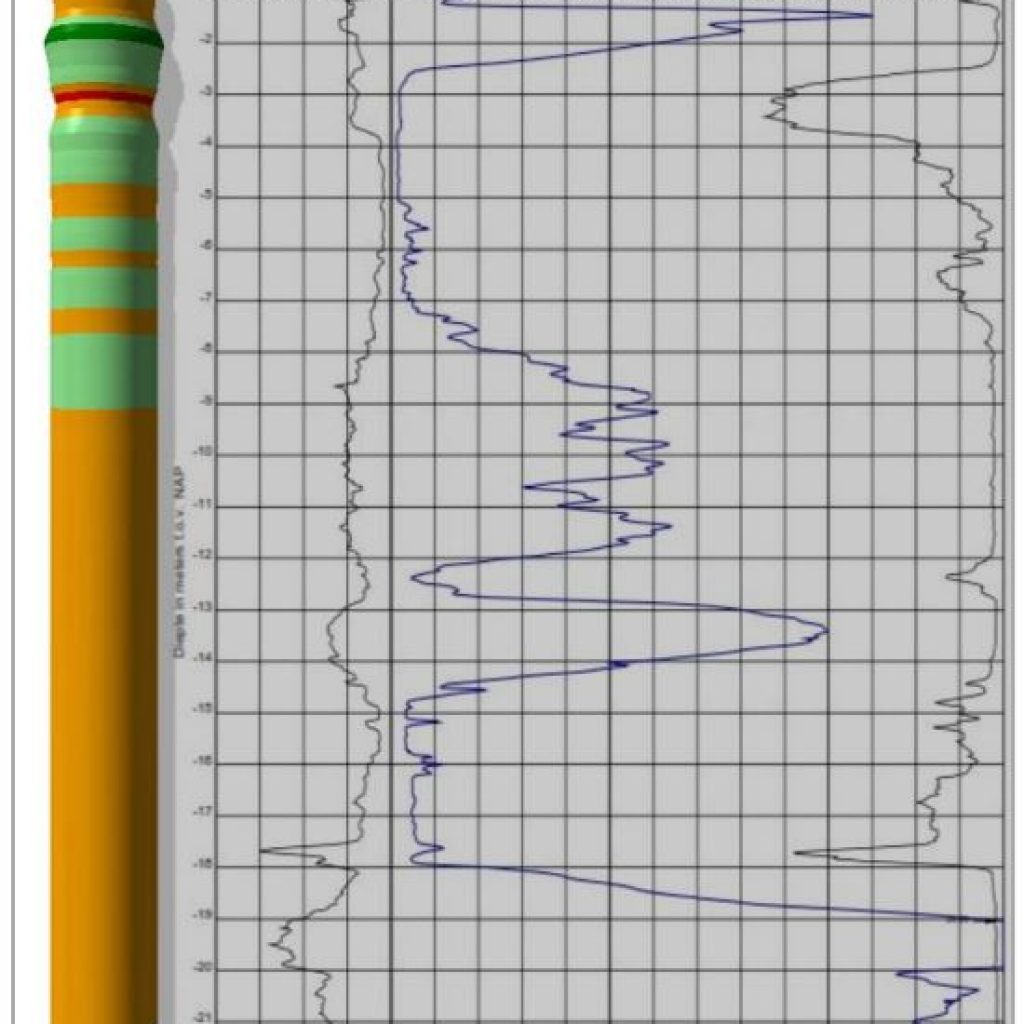

Sonic Logging is performed by lowering sensors in cast-in tubes. By sending a sonic signal through the concrete by the transmitter to the receiver, information about possible defects and concrete area will be obtained.

Sonic Logging is mainly used for bored piles with large diameters and diaphragm walls.

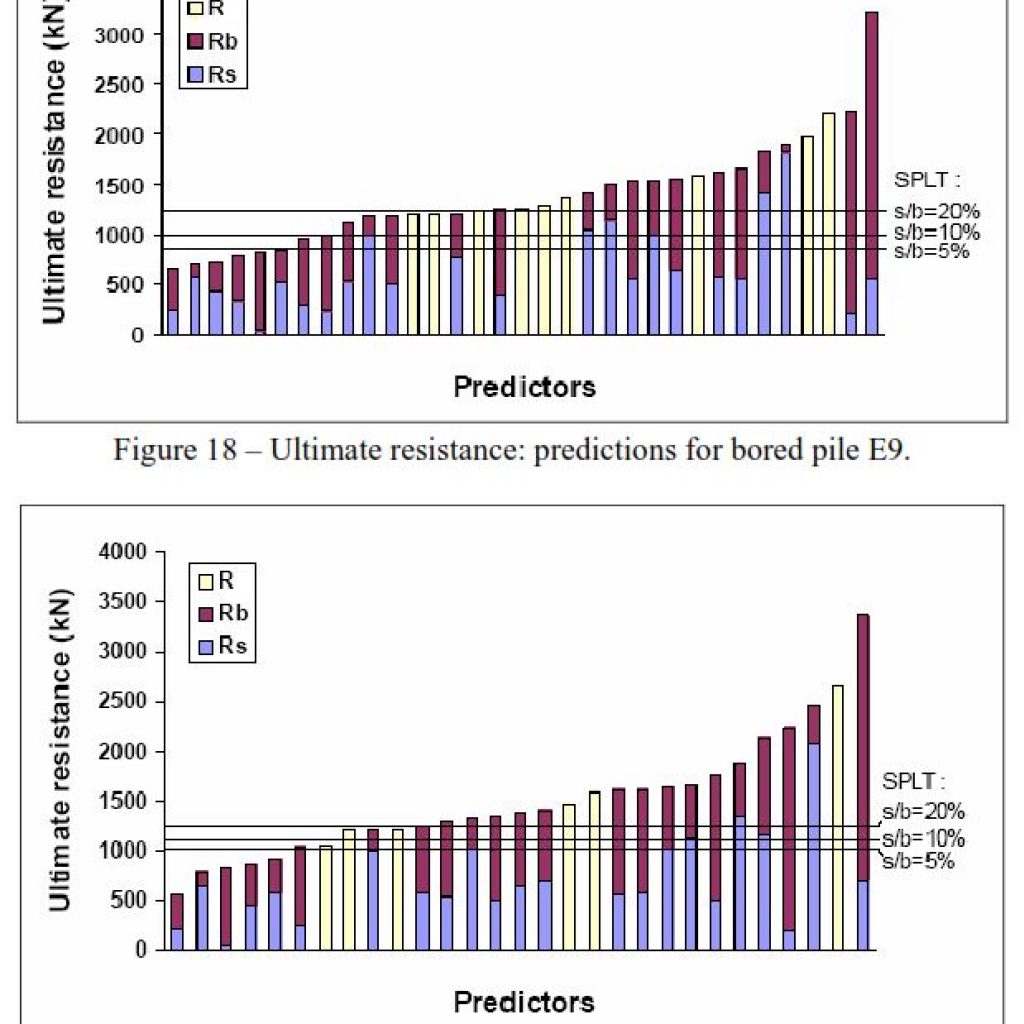

PAPERS AND ARTICLES

Allnamics has made many contributions to international conferences. These publications are available via the Allnamics database. A selection can be found below: