Pile Driving Analysis

Pile Driving Analysis (PDA)

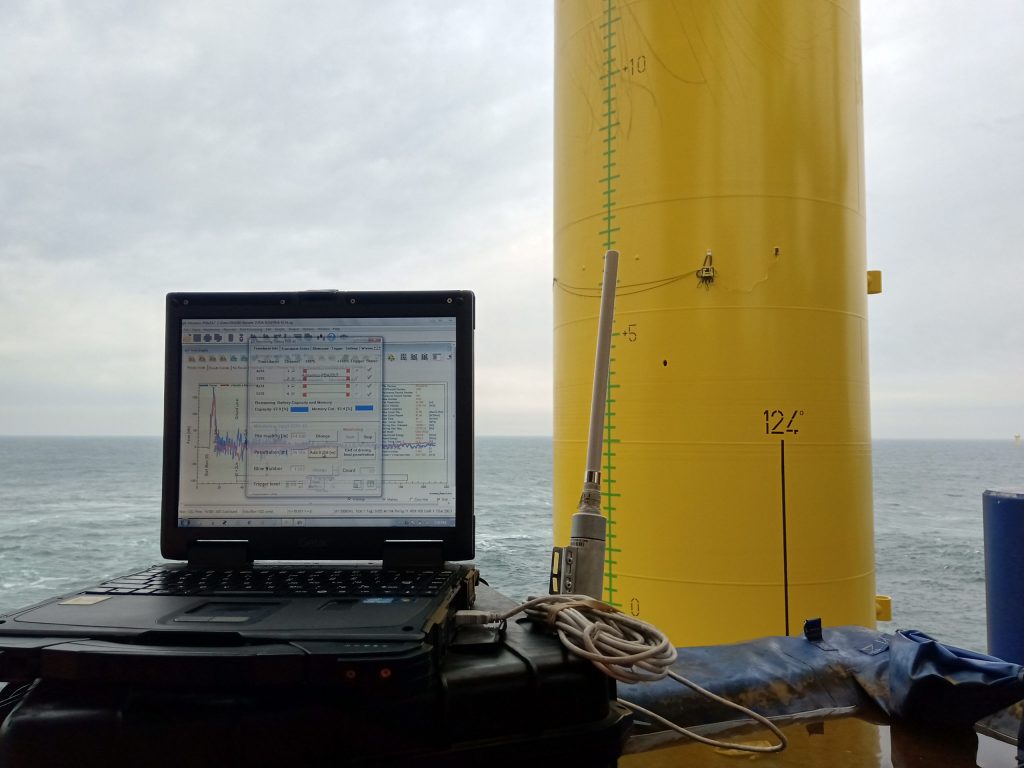

Control and monitoring of the total pile installation process of driven piles. The Allnamics equipment and software for Pile Driving Analysis makes it possible to monitor the performance during driving of pile, hammer and soil. Control the stresses in the pile, the enthru energy in the pile, soil resistances, etc.

Key Characteristics

- Option to transmit data wirelessly by Wi-Fi or by cable or use it as a standalone recording device

- High resolution, easy to operate

- Intelligent sensors & real time sensor control

- Option of with AllWave-DLT for Signal Matching for DLT

- Possibility to export signals for Dynamic Load Testing, fatigue analysis and way more

- Sleep function to delay start of monitoring with hours, days or weeks

- Optimised for use by civil, geotechnical and foundations engineers

- Extensive reporting options in either PDF and MS Word format

- Fully compliant with international standards (ASTM, EuroCode, etc.)

- Supported by the Allnamics Team with more than 50 years of experience

Allnamics' PDR is the wireless data acquisition unit for Static, Rapid and Dynamic Load Testing

Wireless monitoring avoids cable handling during onshore and offshore Dynamic Load Testing

Pile Driving Analysis (PDA)

The total process of pile installation during driving can be monitored with the Allnamics PDA set. PDA stand for pile driving analysis or pile driving monitoring. Parameters of hammer, pile and soil can be monitored to optimize the pile driving process and hammer efficiency, the condition of the pile cushioning, to avoid problems i.e. by limit the pile stresses in both compression and tension, to monitor the behaviour of the soil, entrance in or passing of soil layers and to control the performance related to driveability studies and soil investigations.

The same monitoring set-up can be used for Dynamic Load Testing (or High Strain Dynamic Testing), when the precast pile is redriven after a set-up period, or when an impact is given on cast-in-situ piles. Elaboration of the signals by the Signal Matching technique of AllWave-DLT lead to prediction of the static load-settlement behaviour (DLT).

Pile Driving Analysis (or PDA) reduces the risk of damage to both the pile and the hammer and allows the contractor to drive the pile efficiently to the optimum or required depth.

Dynamic Load Testing (DLT)

PDA and DLT are often confused. Pile Driving Analysis is basically monitoring and control of the pile driving process, for hammer, pile and soil performance.

Dynamic Load Testing (or High Strain Dynamic Testing) can be a fast and cost-effective alternative to Static Load Testing of both concrete and steel piles. During the test, a load is applied to the pile by either an impact hammer or a suitable drop weight. The generated stress wave travels down to the pile toe and back up again to the top of the pile. Near the pile top the stress waves are captured by measuring the strain and acceleration. These signals can then be analysed to assess the pile capacity.

Wireless PDR for Dynamic Load Testing

PDR FOR DATA ACQUISITION

Allnamics has developed a state-of-the-art multi-purpose monitoring system, the PDR. Designed by a multi-disciplinary design team, the PDR meets the pile testing requirements on the construction site in every respect. Options include continuous monitoring of strain and acceleration during pile driving (PDA) and single blow registration for Dynamic Load Testing (DLT), whether at the end of driving or during re-strike. Data collected for DLT can be exported for further analysis with AllWave-DLT Signal Matching software.

THE MONITORING SENSORS

Each measuring system includes two combined sensors for measuring strain and acceleration. The sensors are delivered with a multipurpose template. This template is used for the protection of the sensors during transport and mounting. It is also used as a drilling template ensuring the exact positions of the two holes drilled for each combined sensor. Finally, it contains all necessary mounting materials (i.e bolts and Allen key)

The mounting of the sensors can be monitored by the PDR, to ensure stress-free instrumentation.

The status of the sensors is also continuously monitored before and during monitoring. On the screen of the field computer, the condition of all sensors is presented in real time.

Above or Under Water?

Offshore piles are often driven into the soil, using an impact hammer that can drive the pile underwater. Allnamics has developed special PDA-sensors for application Under Water, able to resist the high pressure of many (hundreds of) meters of water depth.

ALLWAVE SIGNAL MATCHING for DLT signals

AllWave is a Wave Equation Analysing Program (WEAP) based on the Method of Characteristics for one-dimensional stress waves and offers the possibility to simulate the soil behavior according to various soil models (TNO, Smith, and Randolph).

During the Signal Matching process for Dynamic Load Testing, the soil model is adjusted until a good match between the calculated and measured upward travelling wave is obtained. The upward travelling wave contains information on the interaction between soil and pile shaft and toe.

The initial soil model is based on the soil investigation results. CPT’s, SPT’s and other soil investigation results can be imported digitally or digitized using the AllWave Soil Digitizer. Manual input of soil layers and soil parameters is possible as well.

The Signal Matching process is enhanced by several utilities, including AutoMatching support.

SPECIFICATIONS AND CODES

Allnamics equipment for Pile Driving Analysis complies with a.o. ASTM D4945, and EuroCode EN ISO-22477-10, EMC, ESD.

ADVANTAGES

- Wireless transmit data by Wi-Fi or by cable or use it as a standalone recording device

- High resolution, easy to operate

- Intelligent sensors & real-time sensor control

- Extendable to more channels by connecting multiple PDR in leader/follower mode

More info…

If you want to know more about the equipment for PDA, please contact us at info@allnamics.com

Allnamics Pile Driving Analysis ON YOUTUBE

- PDA 2013 Delmag Steel tube with Allnamics PDR

- Monopile for the Wash Tuide Gauge (WTG) near King’s Lynn in the UK

- Under Water Pile Driving Analysis at Wikinger Offshore Wind Farm (OWF) at the Ostsee, Germany

- Pile Driving Analysis and Flange Measurement Offshore Wind WesterMeerWind

- PDA and DLT at Cartagena, Colombia

- Pile Driving Analysis Prefabricated Concrete Pile Junttan Hammer with Allnamics PDR

- Allnamics PDA Pile Driving Analysis for Offshore Monopile

- PDA and DLT tests in Egypt

- Dynamic Load Testing in Switserland

- Dynamic Load Testing and Pile Driving Analysis in Dover UK, with slow motion of a hammer blow

See also our YouTube Allnamics channel and YouKu Allnamics channel