BAM Screw Piles 2.0: Validating Design for ‘De Drie Hoefijzers’ by Rapid Load testing

Titel |

BAM Screw Piles 2.0: Validating Design for 'De Drie Hoefijzers' by Rapid Load Testing |

BAM Screw Piles 2.0: Validating Design for ‘De Drie Hoefijzers’ by Rapid Load Testing |

Author(s) |

Geest, A. van der; Helden, A. van; Bakker, J |

|

Year |

2022 |

|

Language |

English |

|

Where |

11th Int Stress Wave Conference, Rotterdam, The Netherlands |

|

Cite as |

Geest, A. van der, Helden, A. van, & Bakker, J. (2022, September 20). BAM Screw Piles 2.0: Validating Design for ‘De Drie Hoefijzers’ by Rapid Load Testing. 11th International Conference on Stress Wave Theory and Design and Testing Methods for Deep Foundations (SW2022), Rotterdam, The Netherlands. https://doi.org/10.5281/zenodo.7148926 |

ABSTRACT:

Following an amendment on the Dutch Construction Decree in 2016 design parameters for end bearing of pile foundations have been reduced by 30% on January 1st 2017. This amendment was motivated by research on load testing data of foundation piles, which showed an overestimation of end bearing and consequential compromised safety. The new situation potentially results in a considerable increase in installed lengths as well as cross-sectional areas, with possible executional, economic and environmental consequences. A piling contractor can deviate from the

CPT-based design parameters by performing pile load testing. NPR7201:2017 offers the possibility to validate a preliminary design based on freely chosen (assumed) design parameters, by verifying suitability up to design load based test loads.

BAM was awarded the installation of the foundation for housing development project 'De Drie Hoefijzers' in the central train station area in Breda. Because of the presence of sensitive objects in close proximity to the project area, a pile system with low vibration installation is selected. The BAM Screw Pile 2.0 is an optimization of the CFA pile, combining easy installation with minimal relaxation of the soil around the pile tip by introducing a permanent cast steel, serrated drill bit. Experiences with the BAM Screw Pile 2.0 thus far show considerably higher capacities compared to CPT-based design for standard CFA piles. Therefore it was decided to incorporate a pile testing program to corroborate this experience and optimize the design of the foundation.

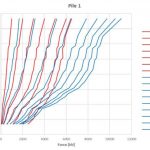

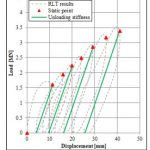

The pile load testing method selected was Rapid Load Testing (StatRapid system). Three test piles following the preliminary design with assumed higher design parameters (20 m in length with a diameter of 800 mm) were subjected to test loads ranging from 6.0 to 7.3 MN (design loads ranging from 2.8 to 3.1 MN). The piles did not exhibit soil mechanical failure and as a consequence the preliminary design was validated. Effectively the approach saved 1 km of pile length, reducing cost by €175.000, as well as a resulting reduction in CO2 production of 80 tons.

DOWNLOAD:

You can download the entire article here after entering your name and e-mail address: