Statrapid tests on CSM panels

StatRapid tests were recently carried out in Breda to check the load capacity of CSM panels, a first. The main constructor has chosen to base the building structure on CSM panels. However, the current Dutch geotechnical standards (EuroCode) provide insufficient guidance for determining the bearing capacity and settlement behaviour. Allnamics carried out six test loads in two days. The tests were Rapid Load Test, using the StatRapid device. The test load was increased in 6 load steps to a maximum of 11,000 kN.

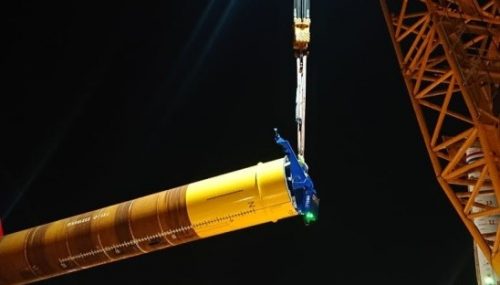

Windpark Fryslân

Allnamics has monitored the pile installation process, recording the hammer blows during pile driving (PDA). Sensors for strain and acceleration were mounted on the inside of the monopiles. No WiFi or cable connection with the sensors is possible from inside the pile to a monitoring computer on deck. Consequently, the Allnamics PDR data acquisition system has been set in the ‘data recorder mode’ (stand-alone monitoring). The response to every hammer blow was stored in the internal data memory, ready to transfer the data to the PC after collecting the PDR from the installed pile.

NEWS

EXPERTS IN FOUNDATIONS

Installation monitoring PDA & VDA

Allnamics develops a wide range of testing equipment. Including the PDR, the data acquisition unit for pile monitoring. During installation or testing, the multipurpose PDR stores all signals on the internal memory and send the signals and test results wireless via powerful WiFi to a monitoring laptop. By connecting multiple PDRs, the number of monitoring channels is almost endless. The PDR is ready for monitoring during impact driving (PDA) and installation by applying a vibratory hammer, VDA.

Pile Load Testing

Allnamics is all about pile testing. With a wide range of testing techniques, Allnamics can test any type of pile on its integrity, bearing capacity, and stiffness. In addition, the founders of Allnamics have been pioneers in the field of pile testing. They have been significant contributors to the development of various pile testing methods, especially Sonic Integrity Testing, Dynamic Load Testing, and Rapid Load Testing.

Driveability Studies for impact and vibratory driving

Pile Driving Predictions are performed to predict the pile, soil, and piling hammer behavior during the installation of foundation piles, including the large diameter monopiles for Offshore Wind Farms (OWF). Allnamics is capable of performing these studies, or Allnamics can deliver its in-house developed AllWave software and train you and your staff to perform driveability studies. For both impact and vibratory driving.

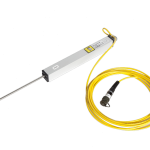

Sonic Integrity Testing (SIT / PIT)

From the inventors of the Low Strain Dynamic Testing, to determine the integrity of piles. Allnamics engineers developed their first SIT equipment back in the 1960s. Based on experience in designing equipment, performing tests, and interpreting test results, Allnamics has developed a state-of-the-art Pile Integrity Testing monitoring system.

FOUNDATION RESEARCH INFO and REUSE EXISTING FOUNDATIONS

Do you want to know the condition of your foundation? Or what maintenance will be required on your foundation in the near future? Do you want to expand your building and are you wondering whether the foundation has adequate capacity? Or reuse the existing foundation for a new bridge, building or other structure? Does the insurance company or a regulatory agency require you to carry out a foundation study? In all these cases, Allnamics is your partner for your foundation research.