STATRAPID: dé methode van snel paaltesten

Paaltesten

Allnamics voert paaltesten uit om de kwaliteit en de geschiktheid van funderingspalen vast te stellen.

Dit kunnen testen zijn om het draagvermogen vast te stellen, het paal-grond gedrag, het last-zakkingsdiagram of om de paal zelf te controleren op onvolkomenheden (SIT, PIT of in Nederlands ‘Hamertje Tik’). Het gaat dan om prefab palen te controleren op breuk en in de grond gevormde palen op insluitingen, paallengte, ernstige doorsnedeveranderingen, etc.

Voor het bepalen van het draagvermogen kan gekozen worden voor volgende opties:

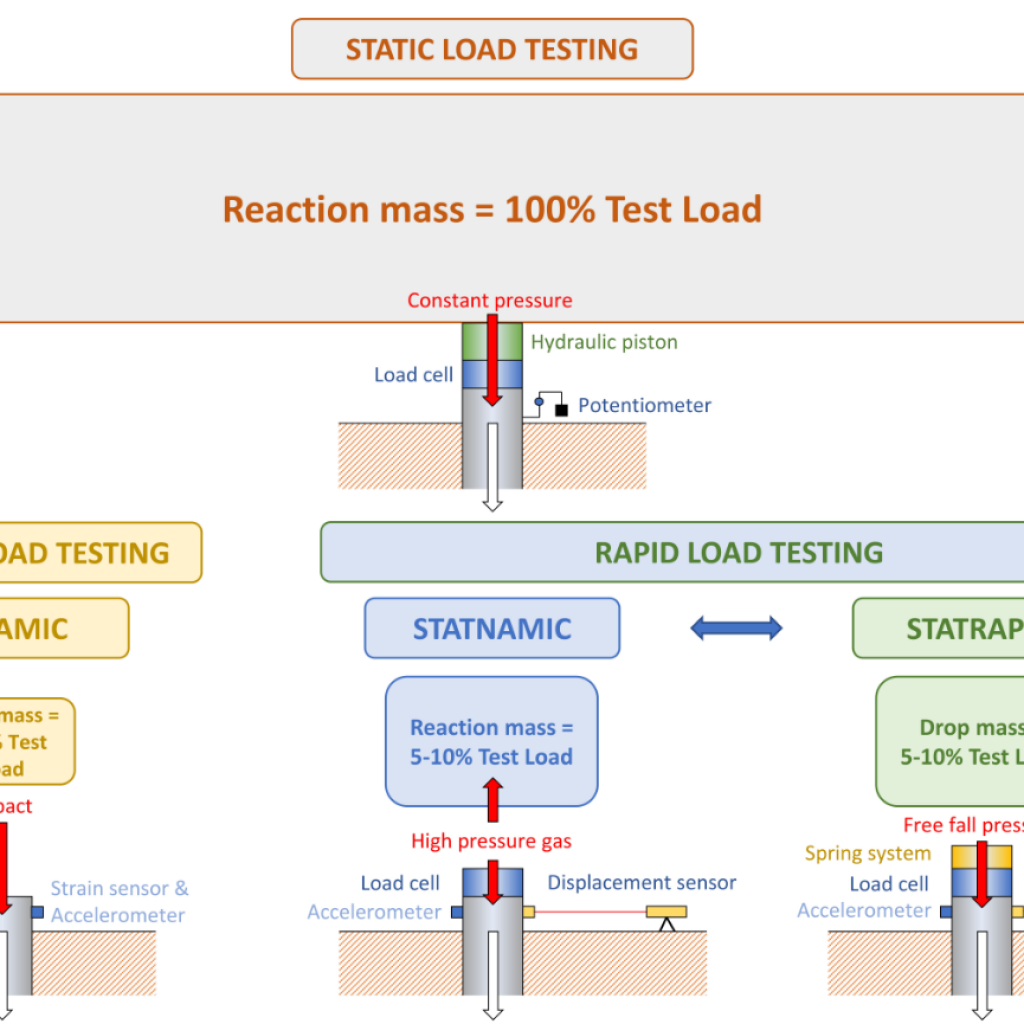

1. Statisch Proefbelasten

2. Bi-directioneel testen

3. Dynamisch Proefbelasten

4. StatRapid Proefbelasten

Alle bovenstaande testen voert Allnamics uit, op het land en offshore, in Nederland en (ver) daarbuiten.

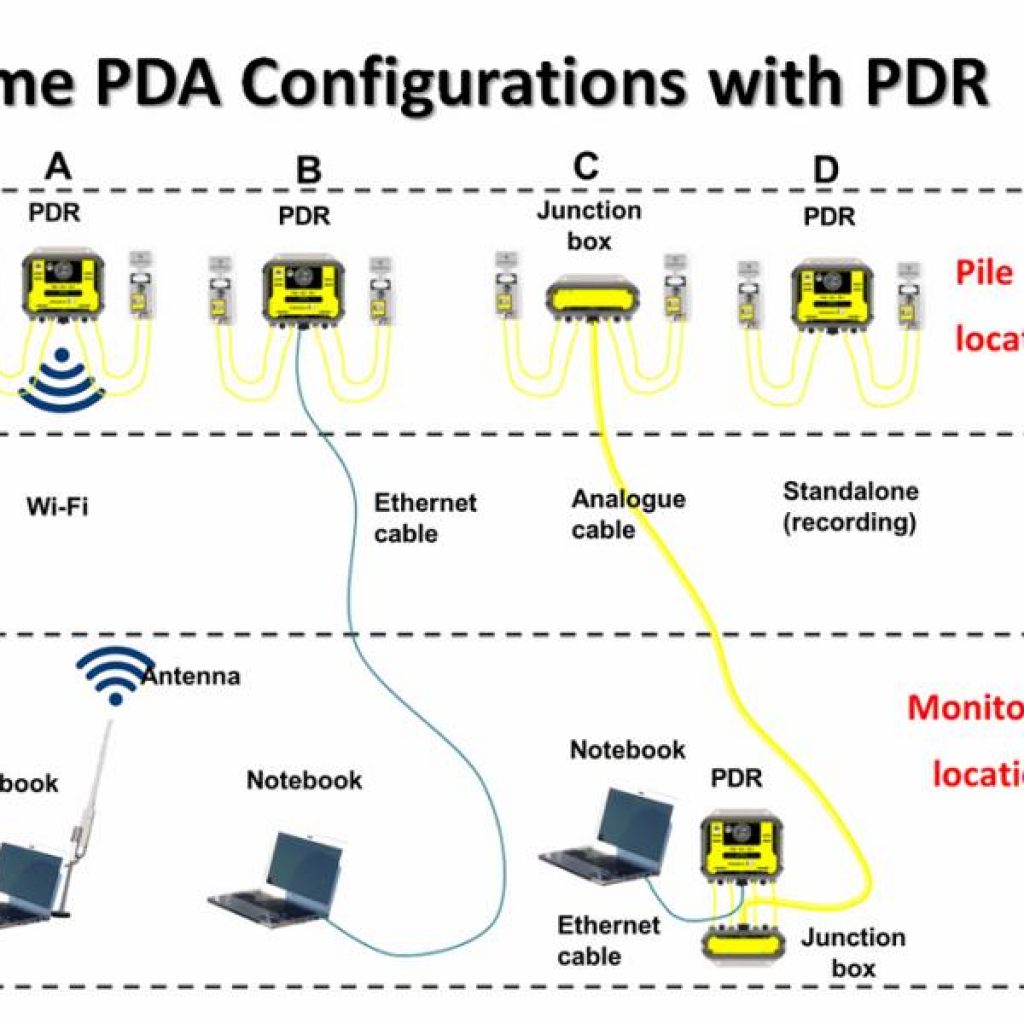

PDA / PDM – Heianalyse

Funderingen dienen betrouwbaar te zijn. Altijd. Daarom worden tijdens de installatie van de funderingspalen metingen aan de paal verricht. Op deze wijze wordt het volledige installatieproces vastgelegd. Controle op o.a. de kalender (aantal slagen per 0,25 m), spanningen in de paal en de efficiency van de hamer (PDM / PDA).

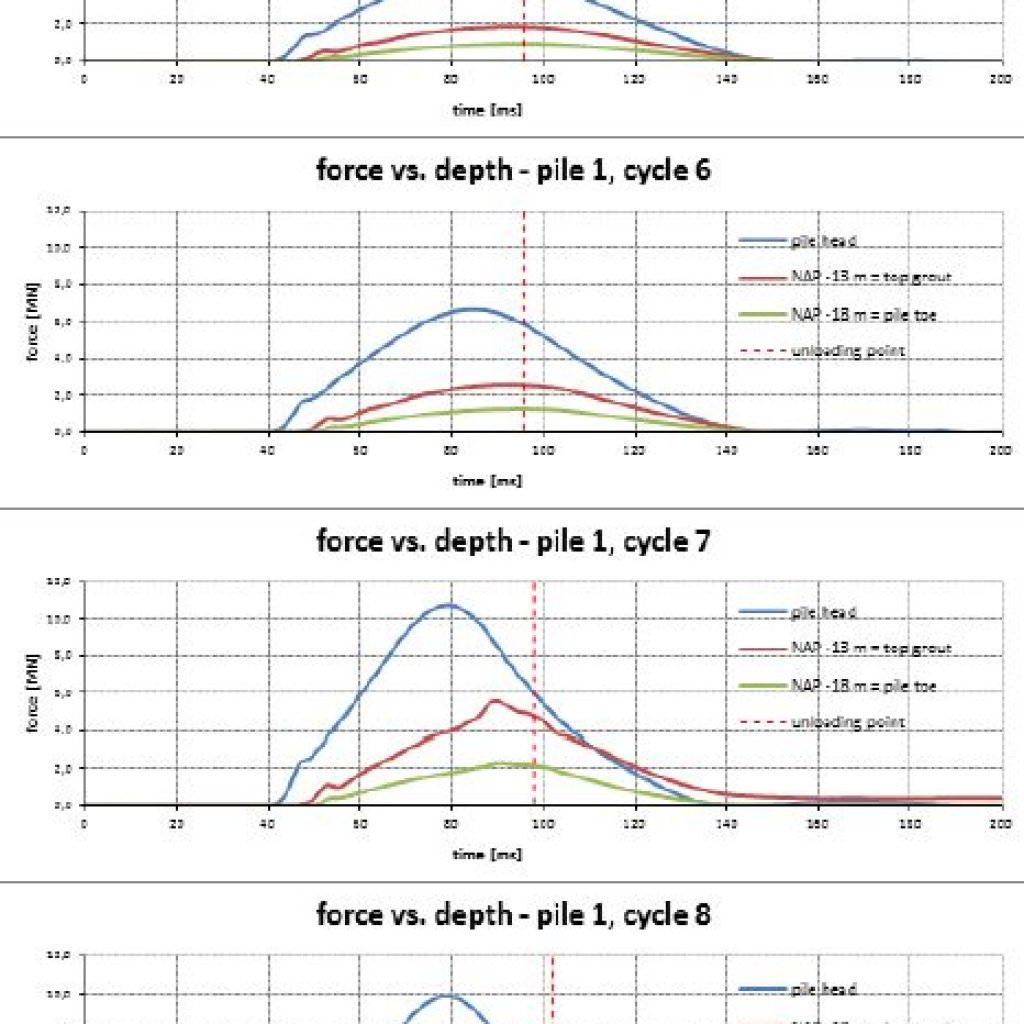

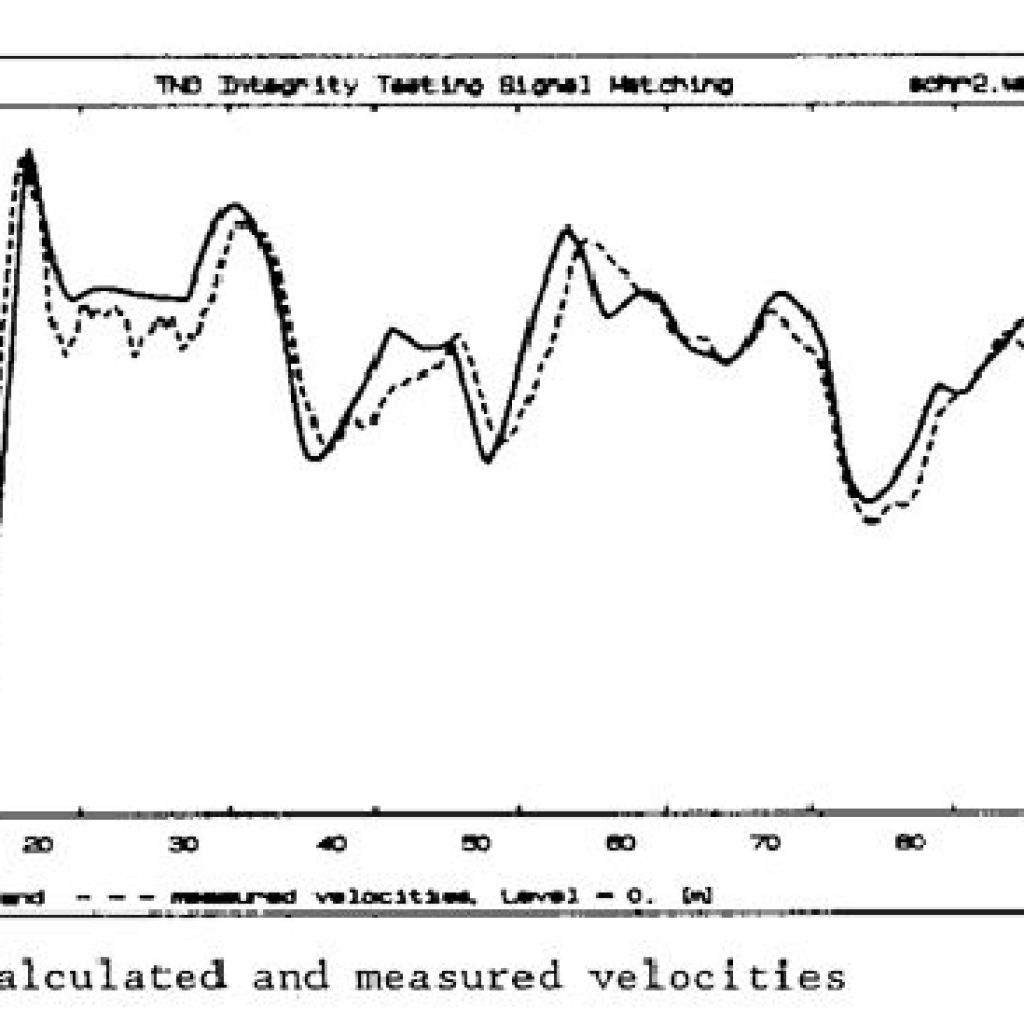

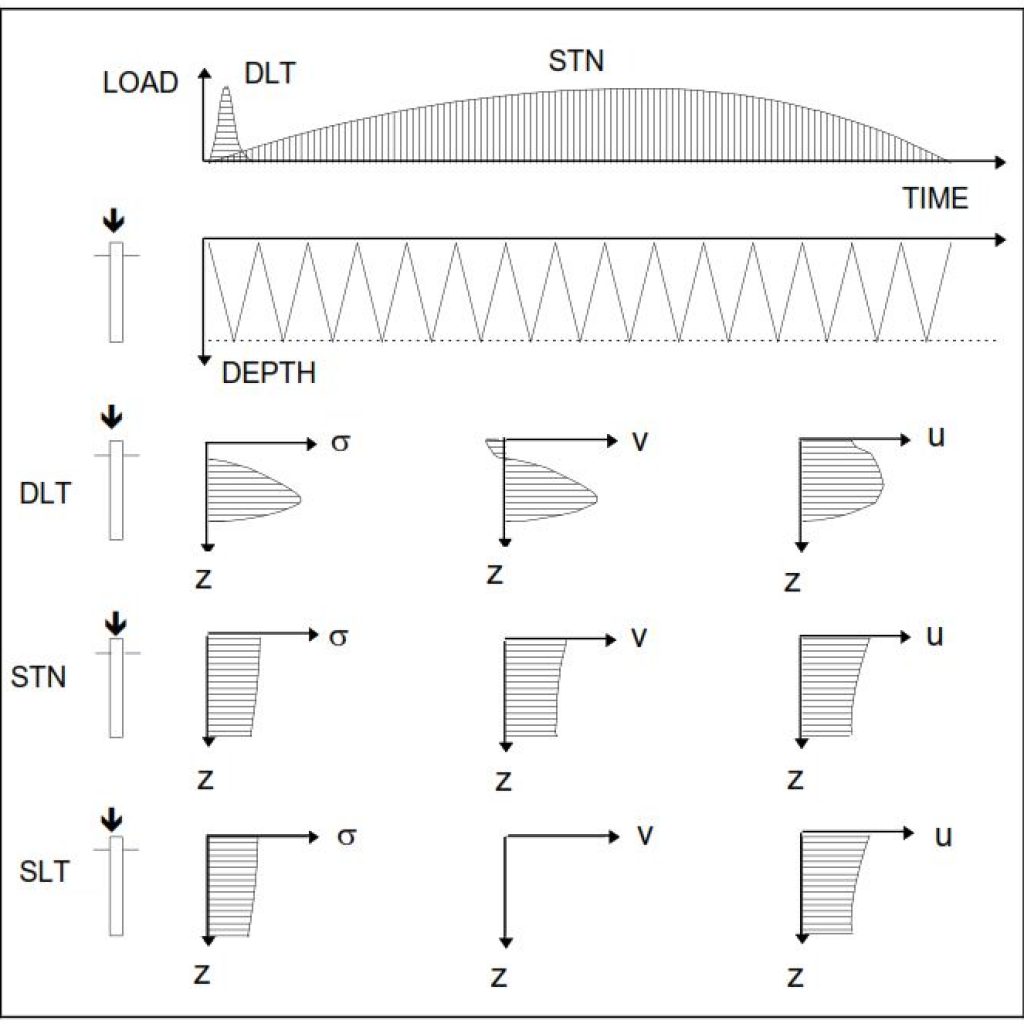

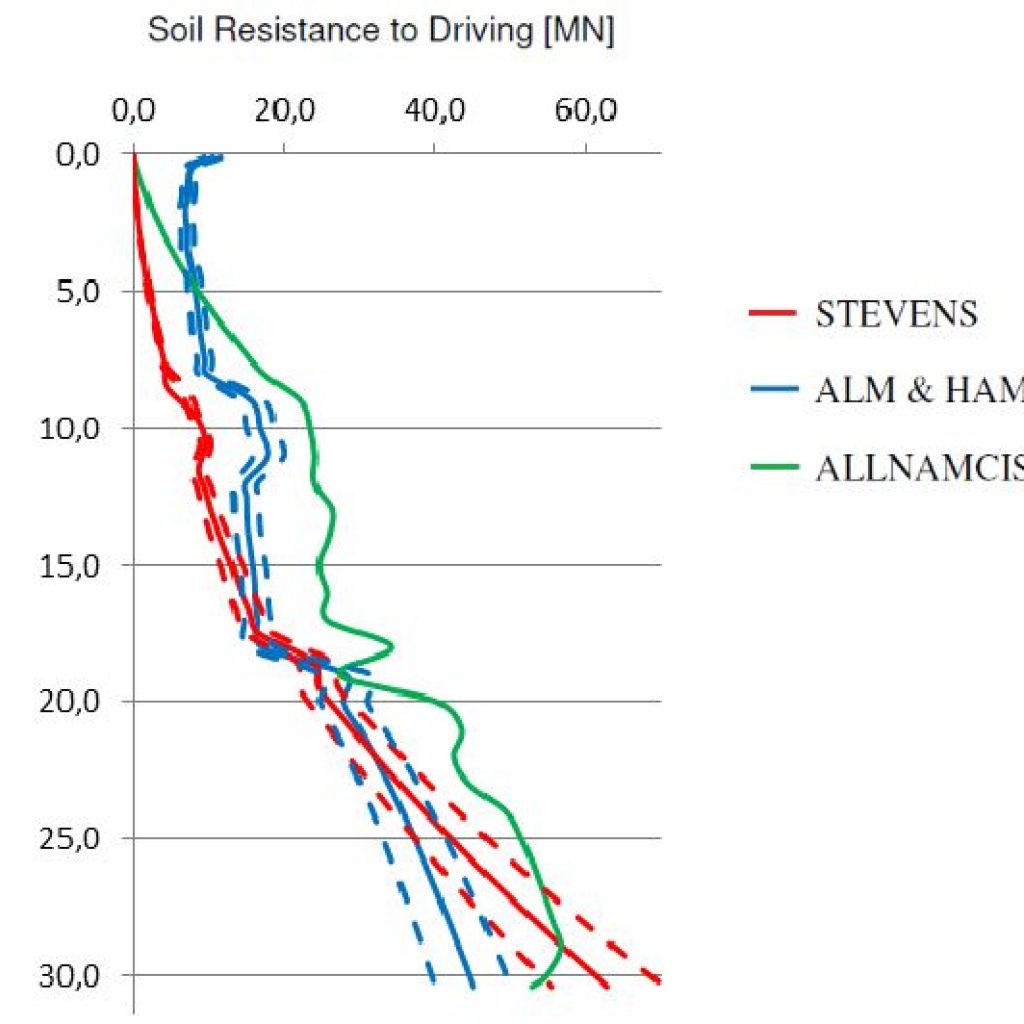

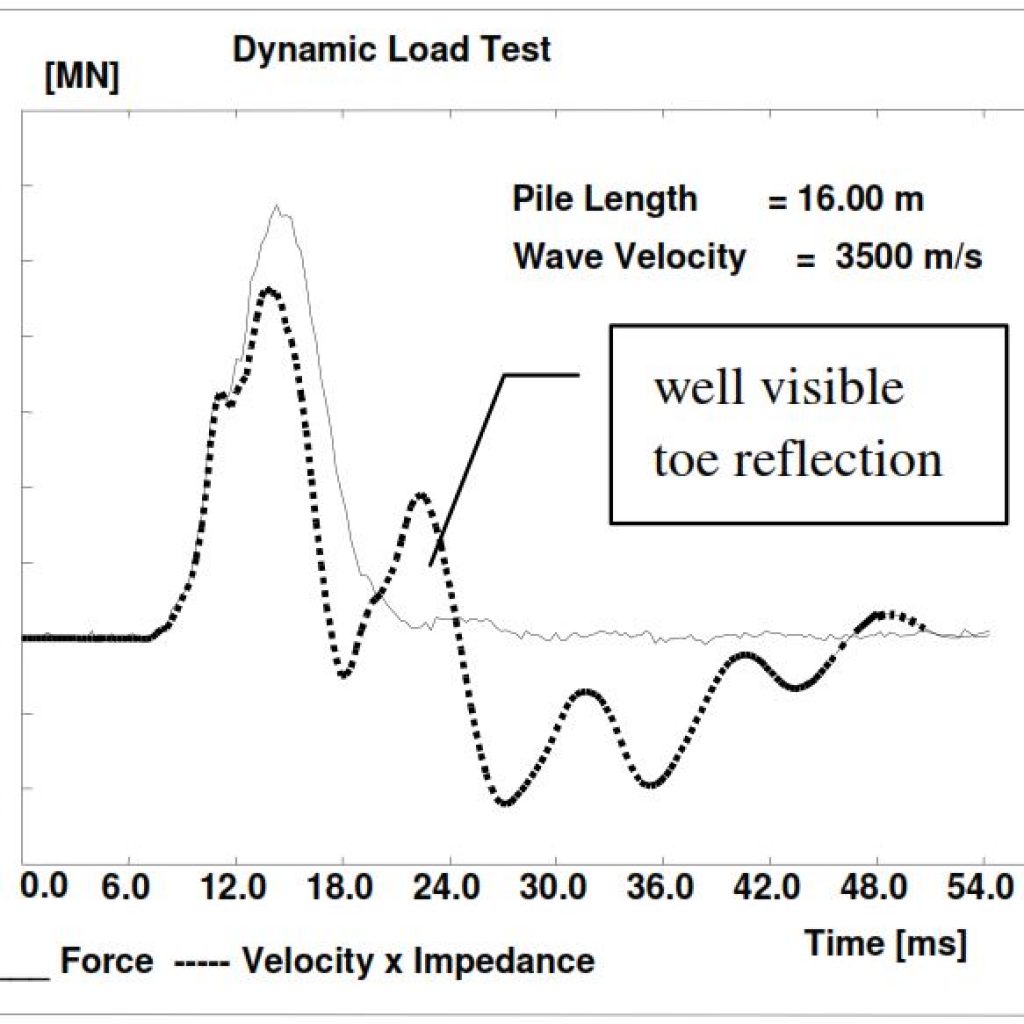

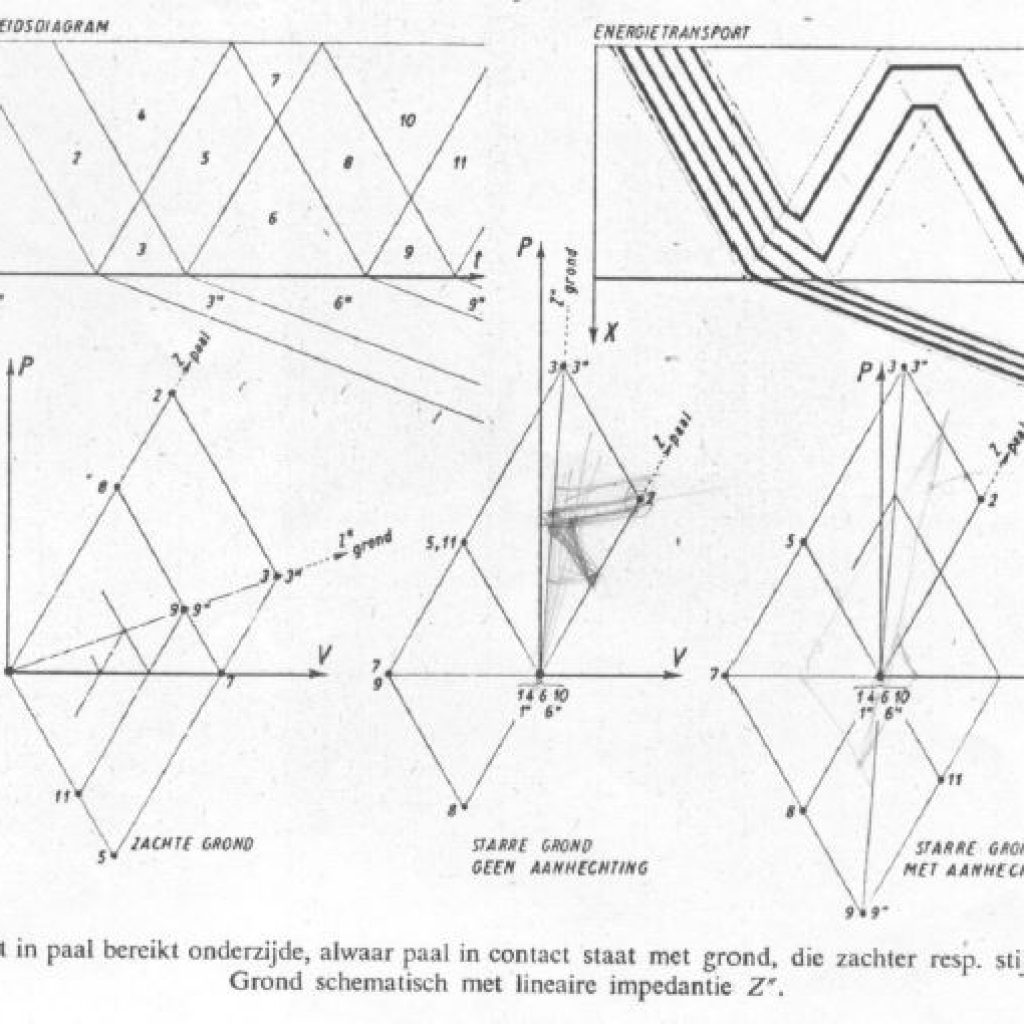

Na het heien tijdens een zogenaamde redrive, kan informatie worden verkregen over het draagvermogen. Bij deze DLT (Dynamic Load Test of Dynamisch Proefbelasten) worden signalen verkregen die middels AllWave-DLT Signal Matchen kunnen worden geïnterpreteerd naar het statisch paalgedrag en bijbehorend draagvermogen.

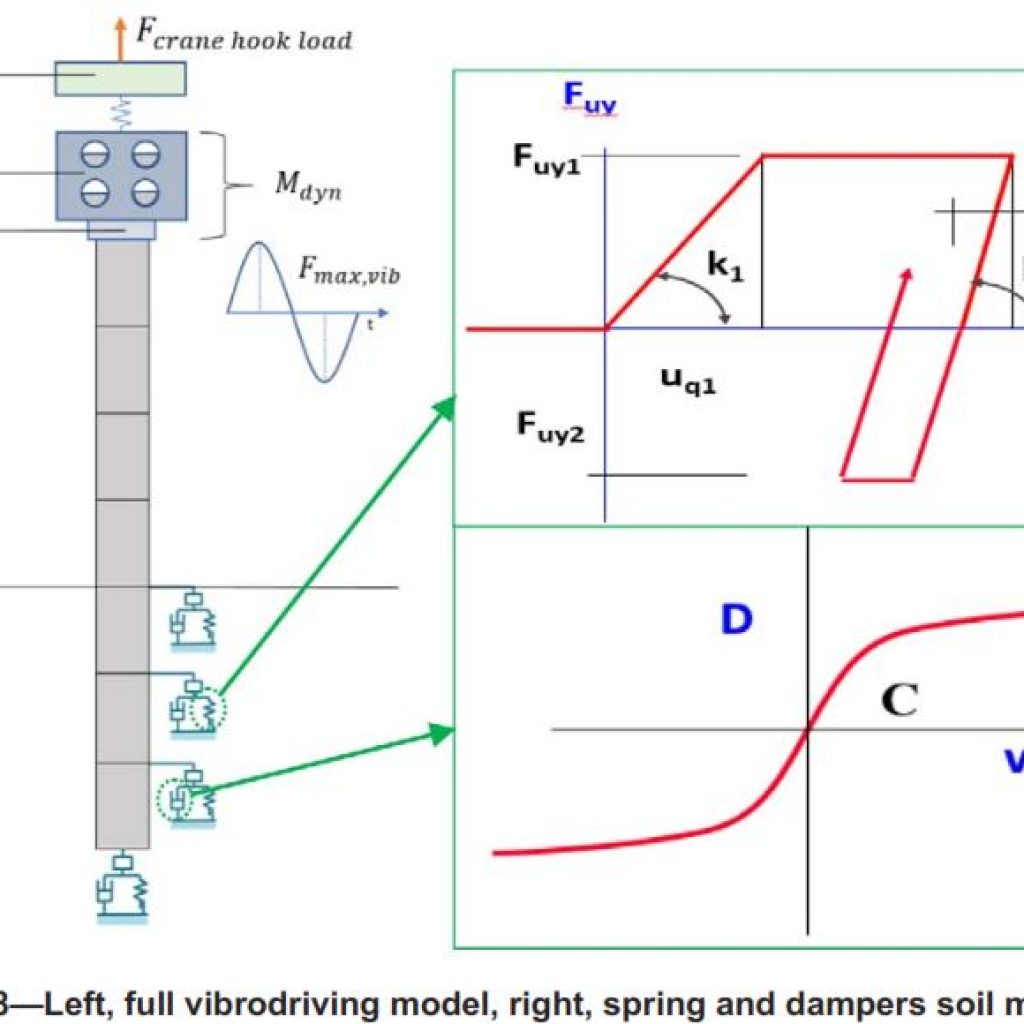

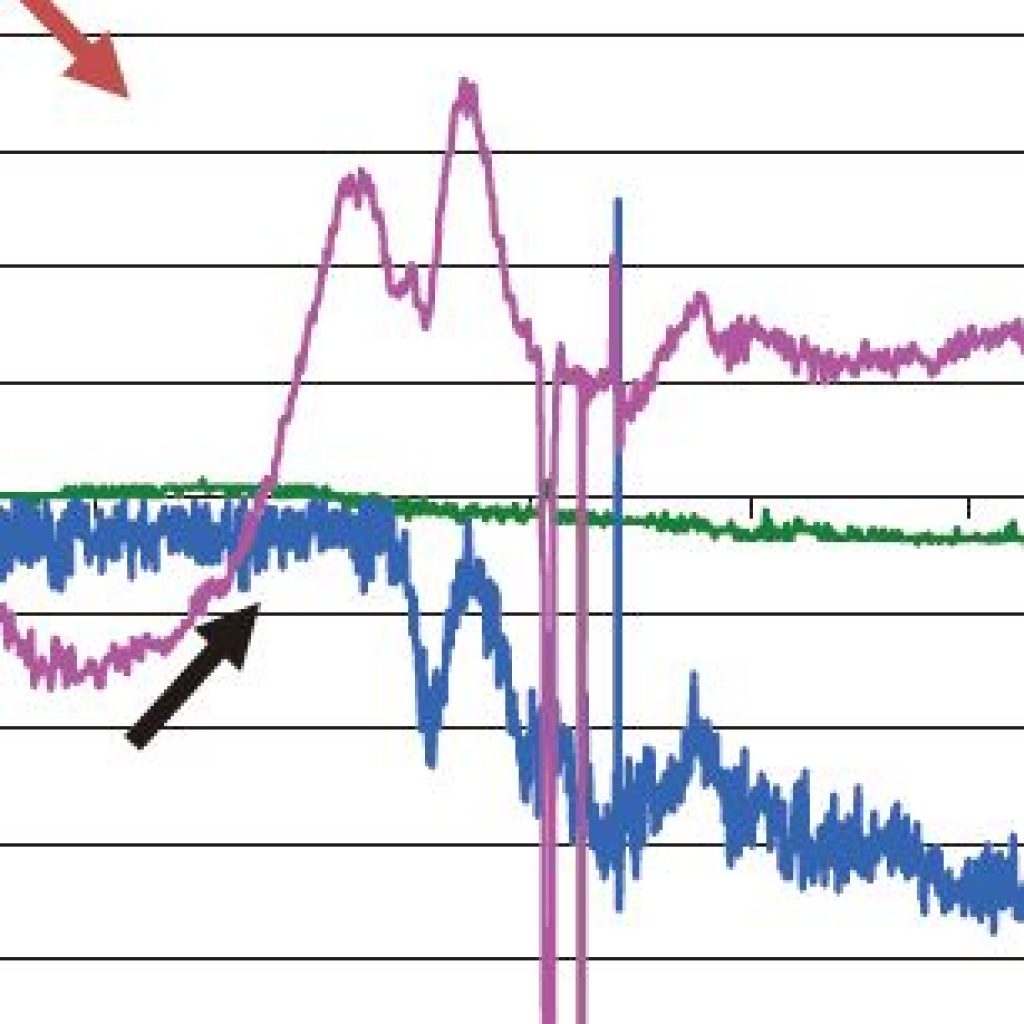

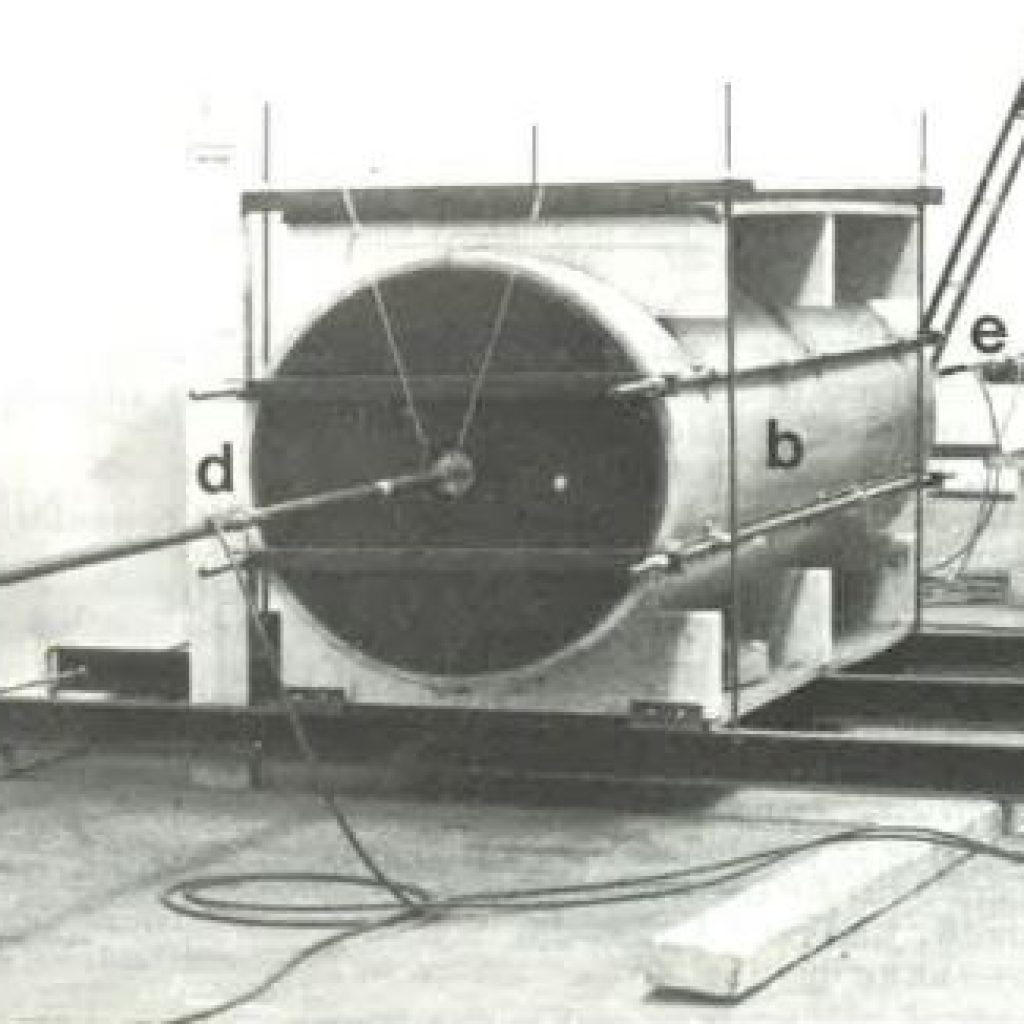

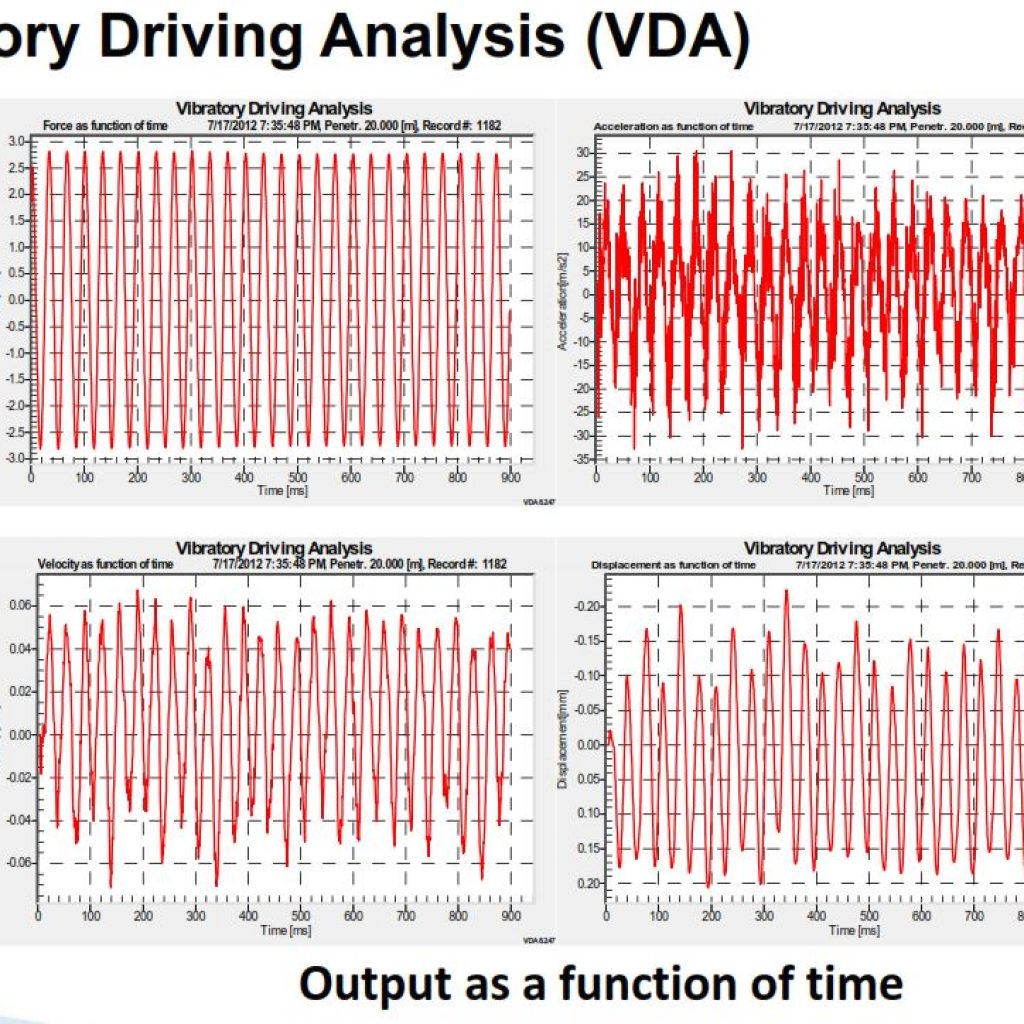

VDM / VDA – Vibratory Driving Monitoring

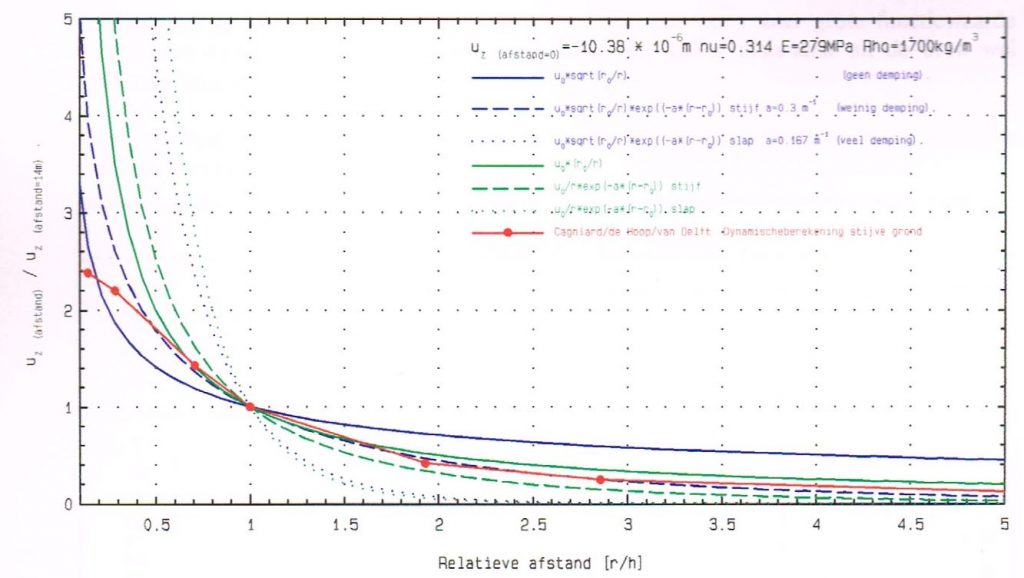

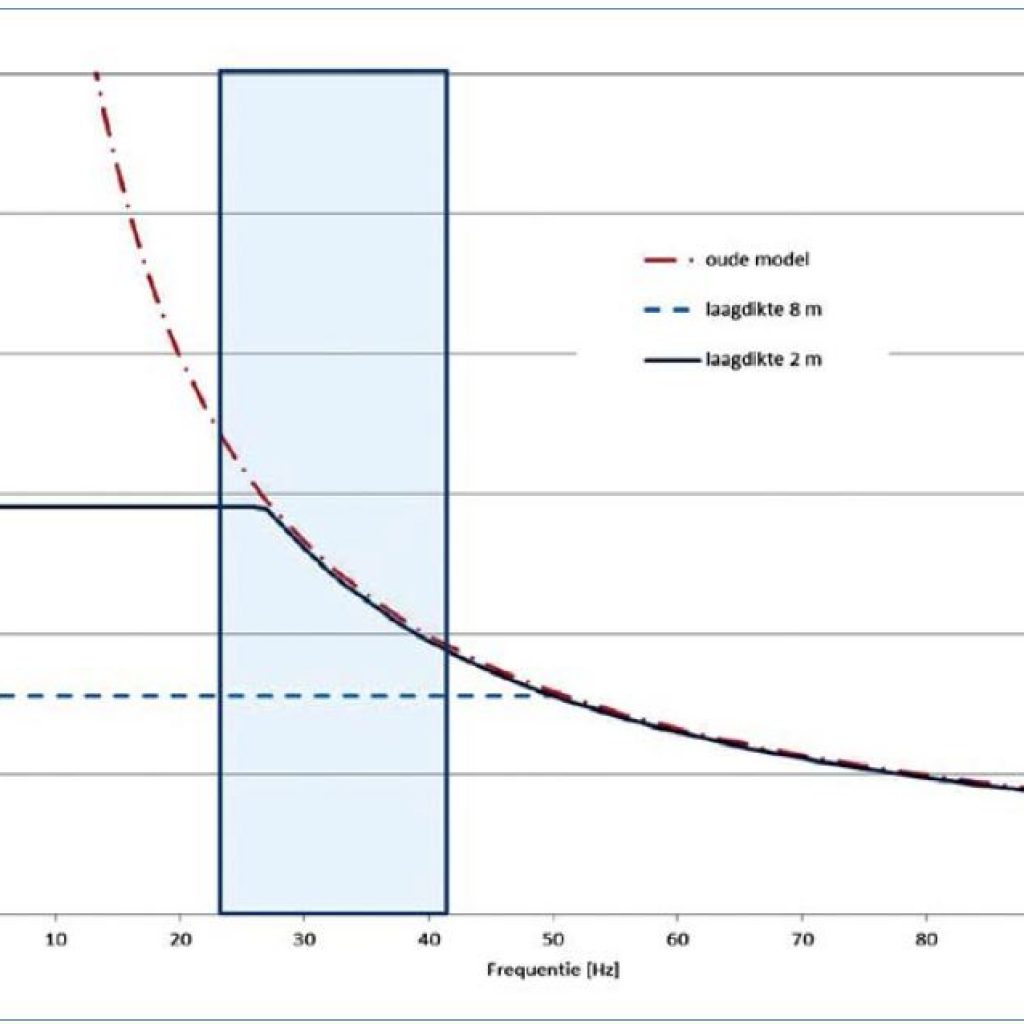

Wanneer de palen niet worden geheid maar naar de funderingsdiepte worden getrild, kunnen vergelijkbare metingen als bij de PDM worden uitgevoerd.

Bij een Vibratory Driving Monitoring worden uitvoeringsaspecten, gedrag van de paal, van de grond en van het trilblok vastgelegd. Bewaken van uiterste waarden van onder andere spanningen, vermoeiingsbijdrage, intrilsnelheden, trilblok frequentie en efficiency, e.d. draagt bij aan de algehele kwaliteitscontrole van met trilblokken geïnstalleerde funderingspalen en monopiles.

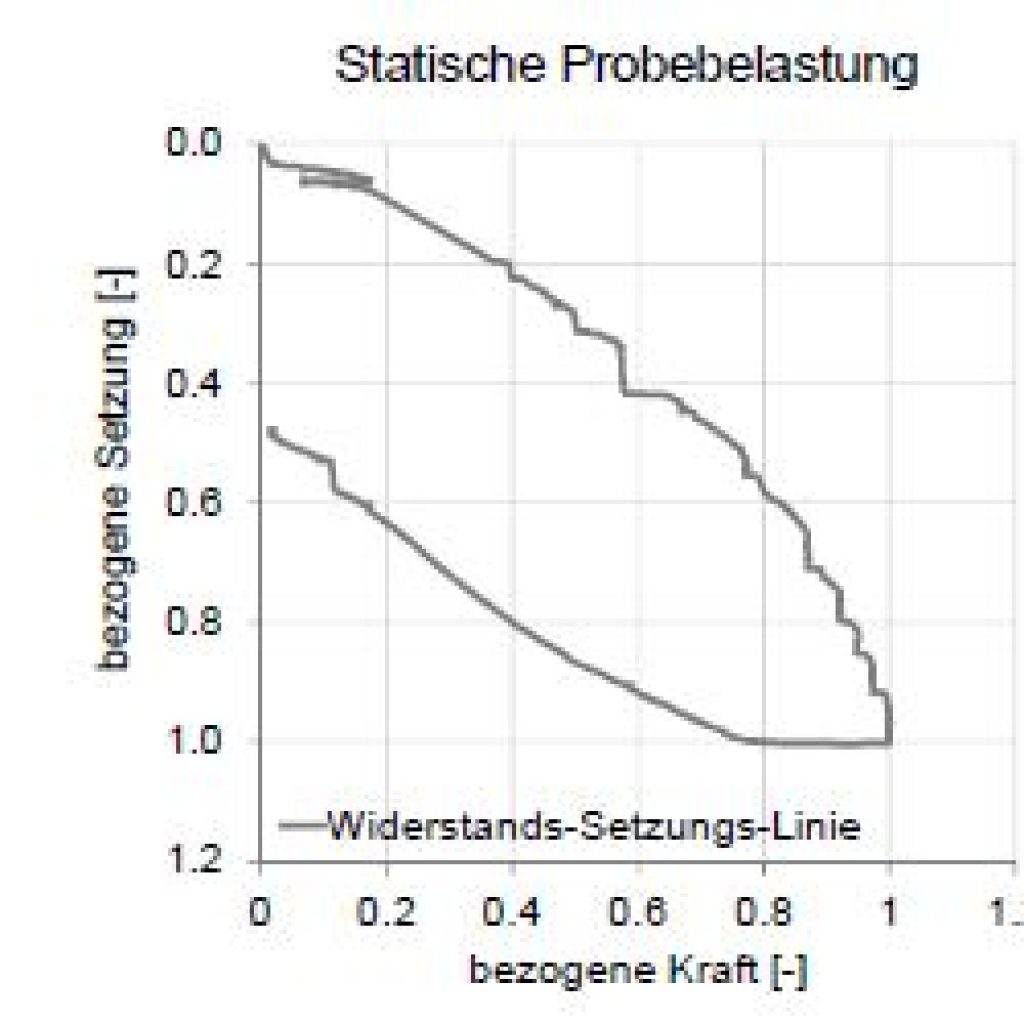

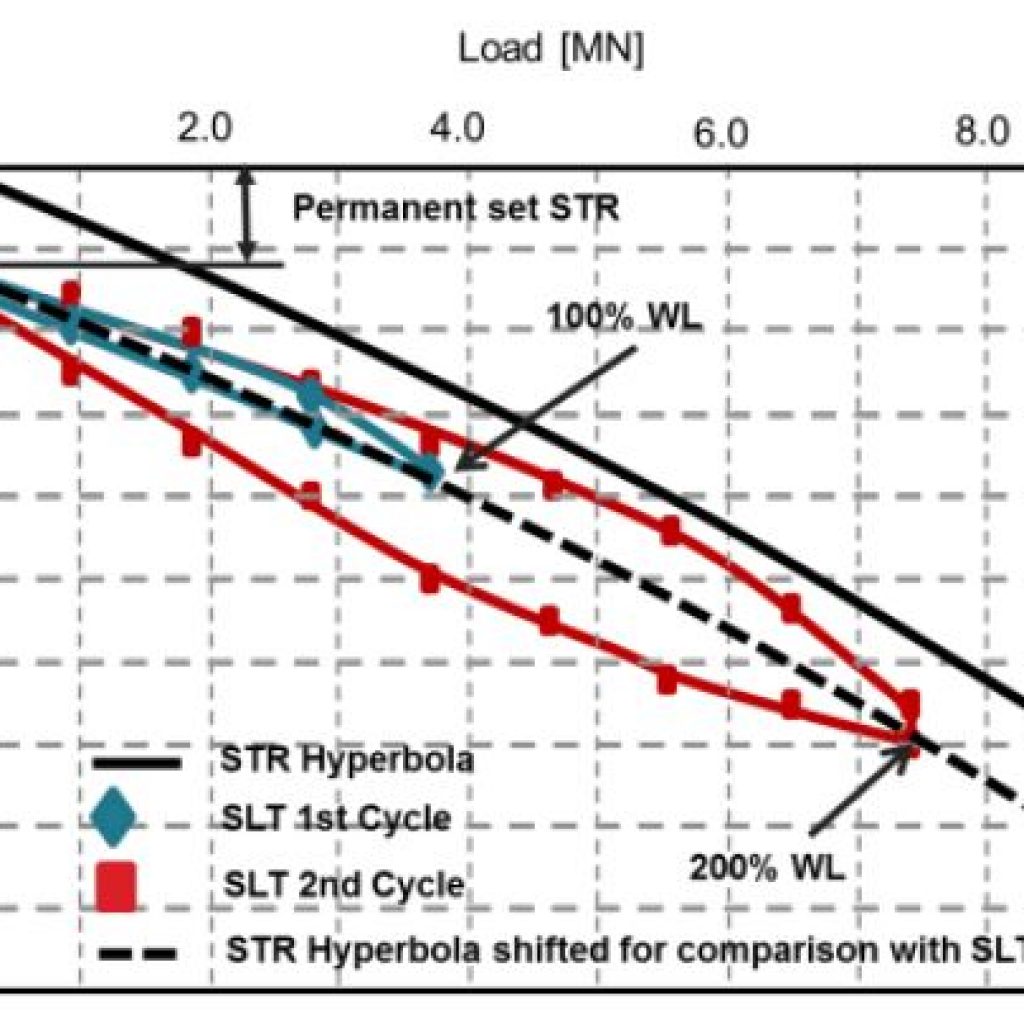

SLT – Statisch Proefbelasten

Allnamics voert statische proefbelastingen uit conform de vigerende codes.

De statische proefbelasting is vooral geschikt voor palen met een wat kleiner draagvermogen. Voor druk- en trekproeven. Verticaal, horizontaal of onder een helling.

Tijdens de test worden kracht en verplaatsingen geregistreerd. Als resultaat volgt een heldere rapportage met het gemeten last-zakkingsdiagram.

Statisch Proefbelasten is vooral geschikt voor:

– Palen met kleine(re) draagvermogens

– Vaststellen van alpha-factoren voor verder gebruik voor het ontwerp van paalfunderingen in het project

– Vaststellen van alpha-factoren voor algemeen gebruik van een bepaald type paalsysteem

– Bepalen van de alpha-factoren voor een nieuw ontwikkeld paalsysteem

– Trouble shooten

Allnamics zorgt voor de volledige uitvoering en levert u de resultaten in een helder en praktisch rapport.

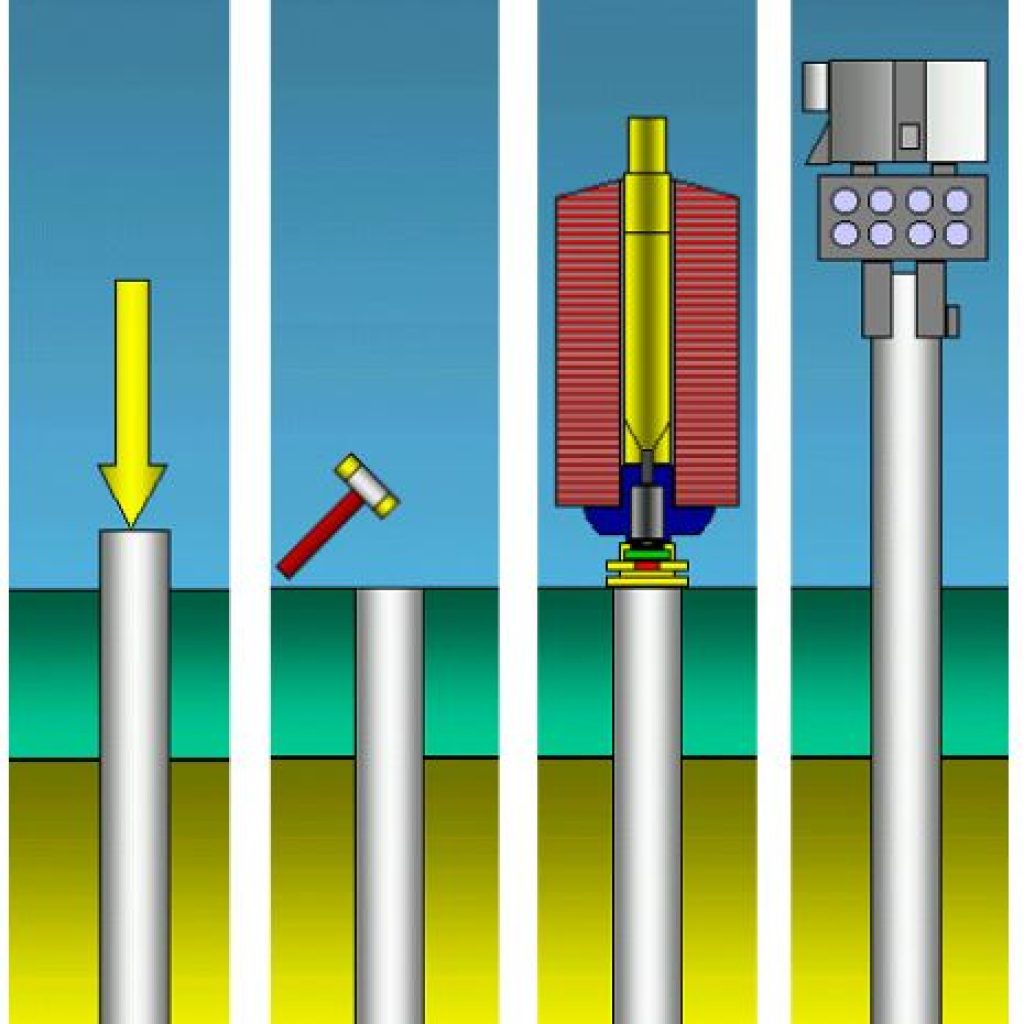

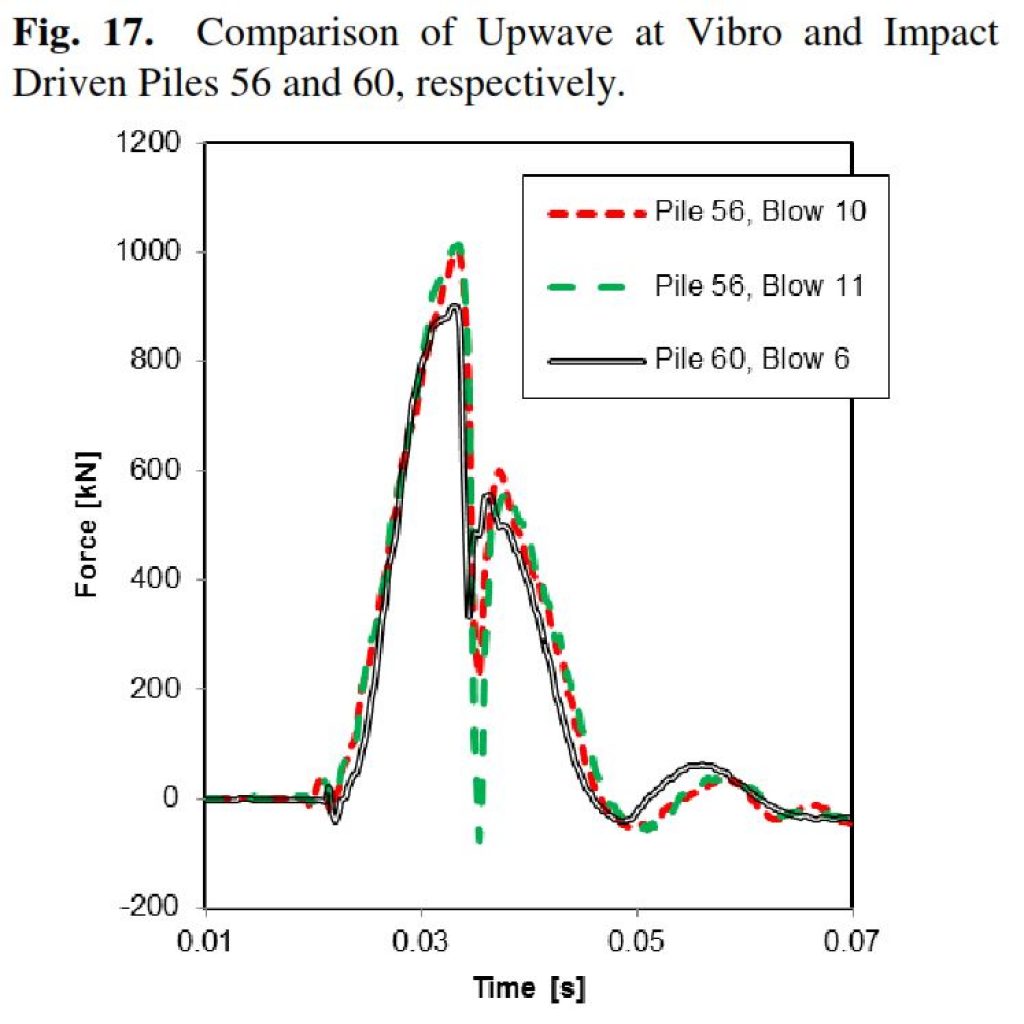

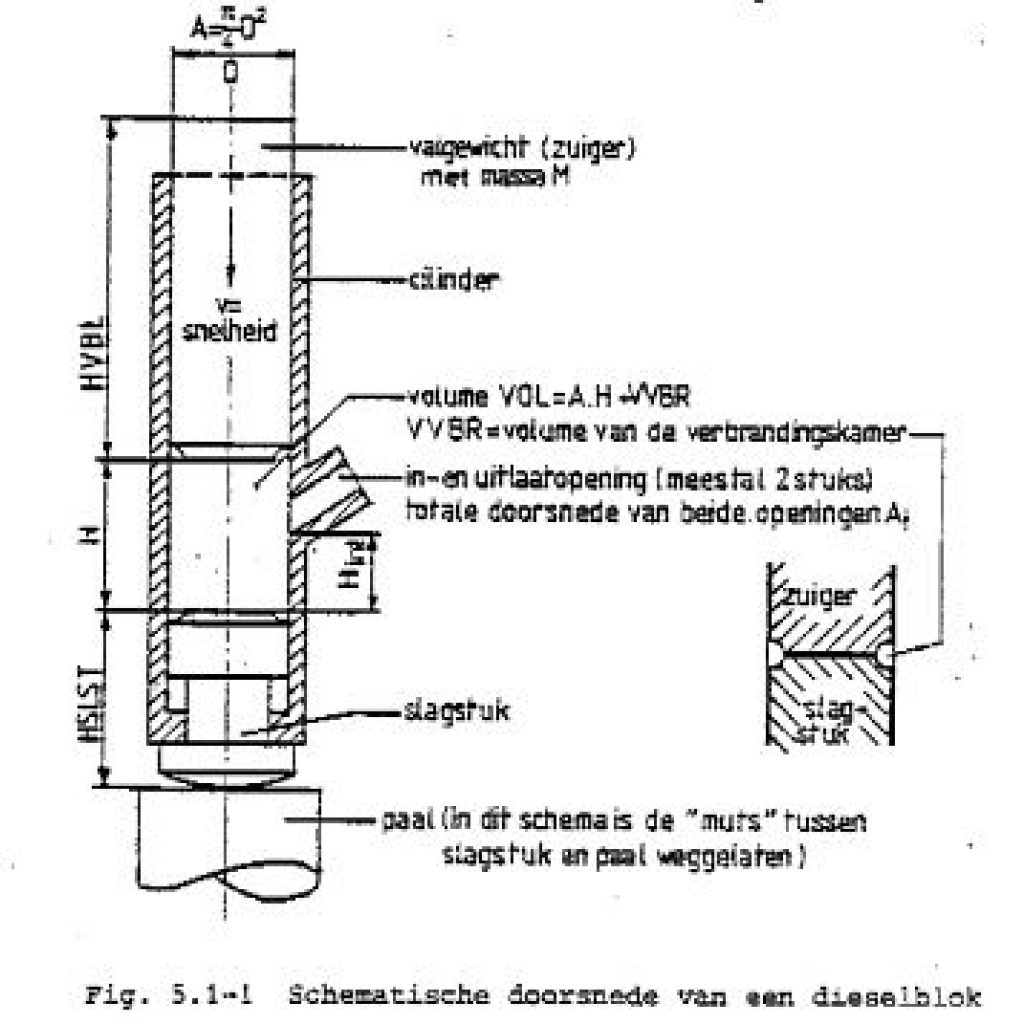

DLT – Dynamisch Proefbelasten

Dynamisch Proefbelasten is in de jaren ’80 ontwikkeld als alternatief voor het statisch proefbelasten. Resultaten van een dynamische proefbelasting zijn vergelijkbaar met die van een statische proefbelasting. Het draagvermogen, het last-zakkingsdiagram en de paalfactoren, alpha-s en alpha-p, kunnen worden bepaald. De oprichters van Allnamics hebben aan de wieg gestaan van de ontwikkeling van het Dynamisch Proefbelasten (PDA, DLT).

Voor de test is een veel kleinere massa nodig om de proef uit te voeren. Voor geheide palen is het heiblok vaak voldoende.

Toepassingen zijn vooral:

– Palen met grote(re) draagvermogens waar het mobiliseren van statische krachten niet praktisch of te duur wordt, zoals bij offshore palen

– Prefab heipalen, omdat deze de grote spanningen van de test kunnen weerstaan. Daardoor minder geschikt voor in de grond gevormde palen

– Palen met een gelijkmatige doorsnede. Grote vormveranderingen leiden tot grotere onnauwkeurigheid en mindere betrouwbaarheid van de resultaten

– Offshore en nearshore projecten

Allnamics is specialist in het uitvoeren van Dynamisch Proefbelasten, waar ook ter wereld.

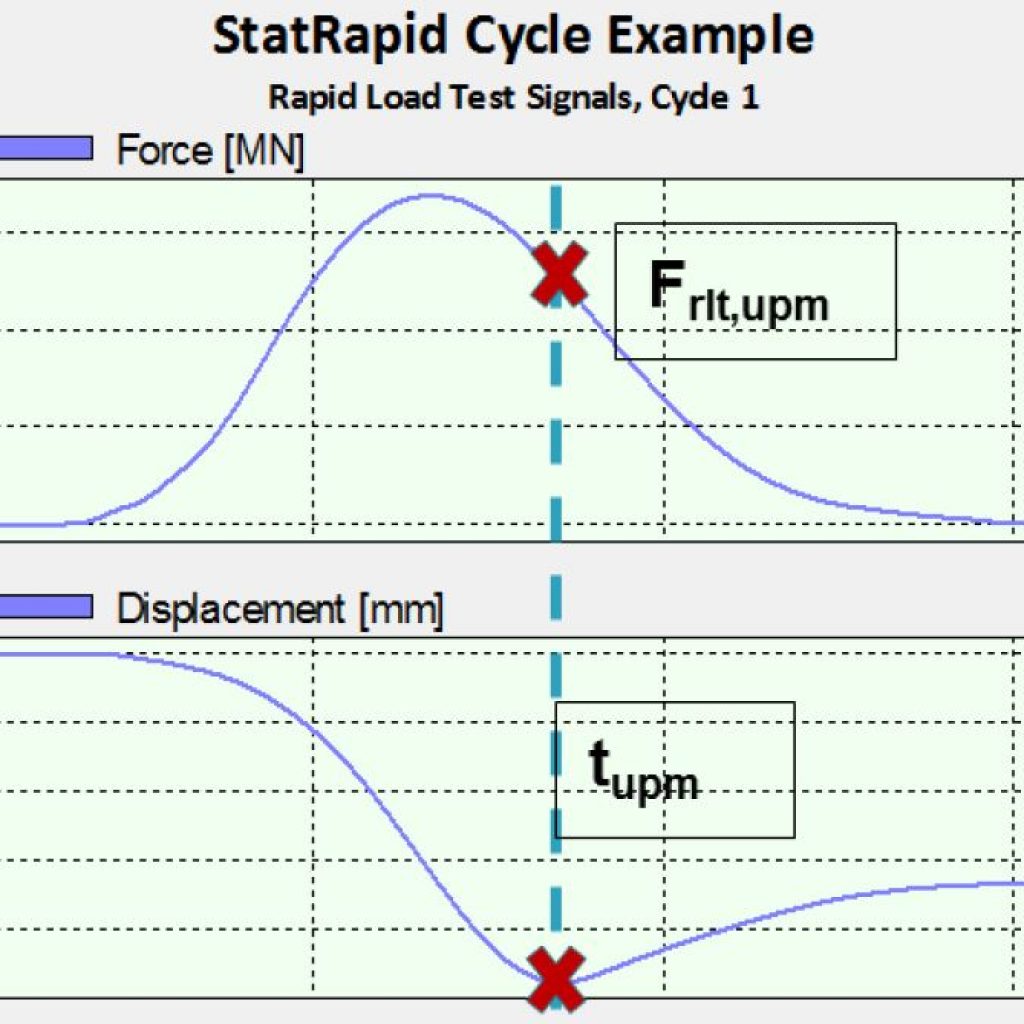

RLT – StatNamic Belastingtesten

Allnamics kan testen tot 16 MN testen uitvoeren met de StatRapid. Voor nog hogere belastingen kan Allnamics gebruik maken van de StatNamic testmethode. Met deze testmethode zijn belastingen tot 65 MN, en binnenkort ook tot 150 MN, mogelijk.

Wilt u meer weten over StatNamic testen? Neem dan contact op met Peter Middendorp pmiddendorp@allnamics.com

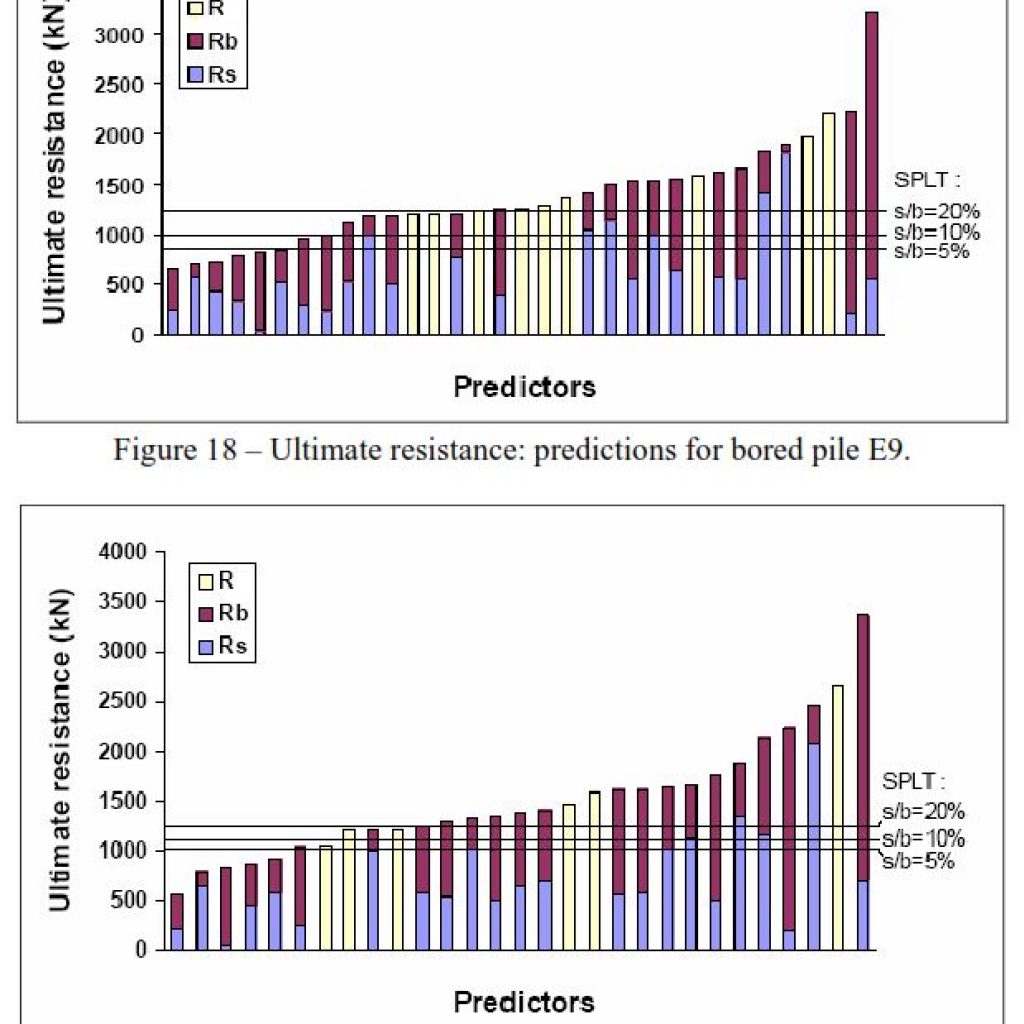

Bi-directional test

Bi-Directioneel Testing is een alternatief op de statische proefbelasting voor in de grond gevormde betonnen palen. De kracht wordt niet aan de kop, maar halverwege aangebracht, via een vernuftig device, de cell. Daarbij wordt het bovenste deel omhoog gedrukt en werkt als een soort van tegengewicht om het onderste deel naar beneden toe te belasten. Na afloop van de test wordt het last-zakkingsdiagram geconstrueerd dat zich laat vergelijken met die van een statische proefbelasting.

Bi-directionele testen wordt vooral toegepast bij paaltesten op boorpalen met grote(re) draagvermogens, waarbij voldoende schachtwrijving kan worden gemobiliseerd om tegenkracht te genereren voor het mobiliseren van schacht- en puntweerstand van het onderste deel.

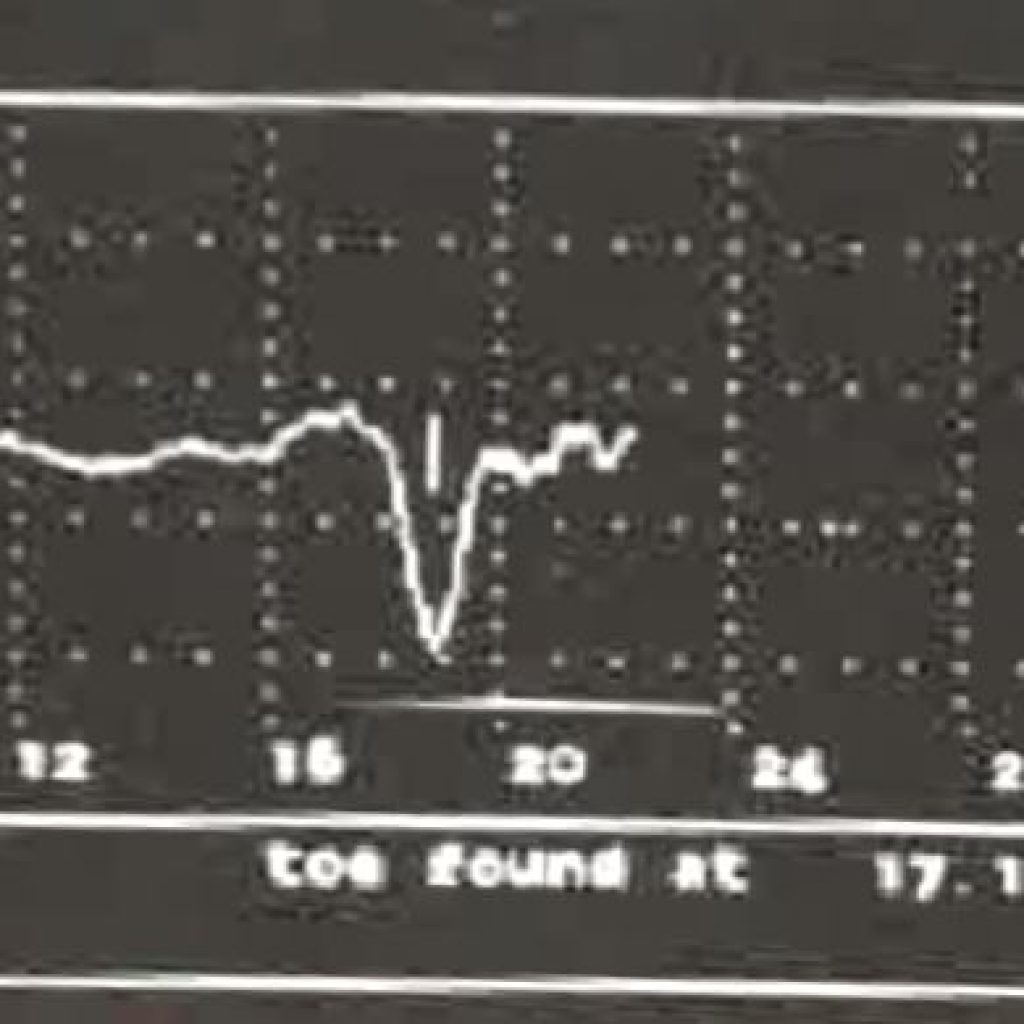

Hamertje Tik

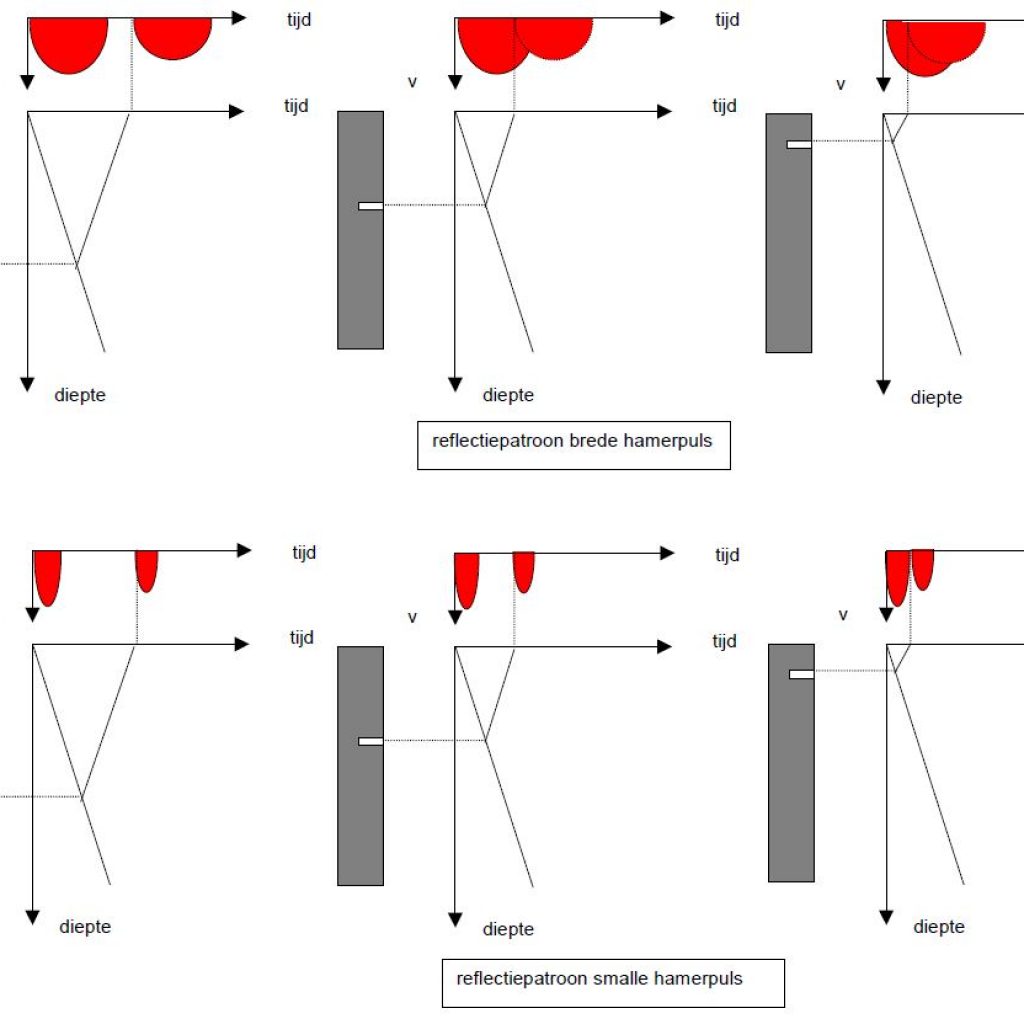

Pile Integrity Tests, in het Nederlands bekend als ‘Hamertje Tik’ is een methode welke in de jaren ’70 in Nederland is ontwikkeld, door de oprichters van Allnamics.

De test is vooral bedoeld voor het vaststellen van imperfecties in de paal. Breuken, doorsnedeveranderingen, grondinsluitingen en andere onvolkomenheden kunnen worden vastgesteld.

Vaak is dit type test een eerste check op de uitvoering van in de grond gevormde palen.

Sonic Logging

Alternatief voor het ‘hamertje tik’ is de techniek van het Sonic Logging. Daarbij worden een aantal buizen in de paal gestort. Na uitharding van het beton worden de metingen gestart door een zender en een ontvanger in de buizen te laten zakken.

Deze meting is vooral geschikt voor in de grond gevormde palen met grotere diameters.

PAPERS EN ARTIKELEN

Allnamics heeft vele bijdragen geleverd aan internationale congressen. Die publicaties zijn beschikbaar via de Allnamics database. Een greep daaruit: